The production of lithium-ion batteries is rapidly increasing, driven by growing demand for electric vehicles (EVs) and renewable energy storage. Lithium-ion battery manufacturers are seeking to scale operations at an unprecedented rate, while maintaining quality, uniformity, traceability, and safety in their battery products.

The Thermo Scientific LInspector in-line measurement and control system addresses that demand by detecting defects in lithium-ion battery electrode coatings, electrode calendering, and separator films during manufacturing while reducing waste and improving battery quality.

The LInspector measurement and control system offers a combination of improved basis weight determination, increased scan coverage, measurement precision, and speed and sensor accuracy, together with novel remote instrument health and status monitoring capabilities. These developments enable coating and thickness control with exceptional accuracy, allowing manufacturers to deliver quality lithium-ion battery products at scale. The new system also includes innovative diagnostic display screens and data reporting purpose-built for battery factory environments.

“Lithium-ion battery manufacturers need confidence that they can detect exceptionally small defects in their products. The LInspector measurement and control system enables battery manufacturers to consistently qualify the thickness and coating uniformity of battery electrodes during the production process at faster speeds and with greater resolution than ever before,” says Tam Nguyen, senior gaging product line manager at Thermo Fisher. “The LInspector measurement and control system has intelligent instrument performance monitoring (IPM) with secure data archival and full traceability of product defects.”

Thermo Fisher Scientific http://www.thermofisher.com/battery

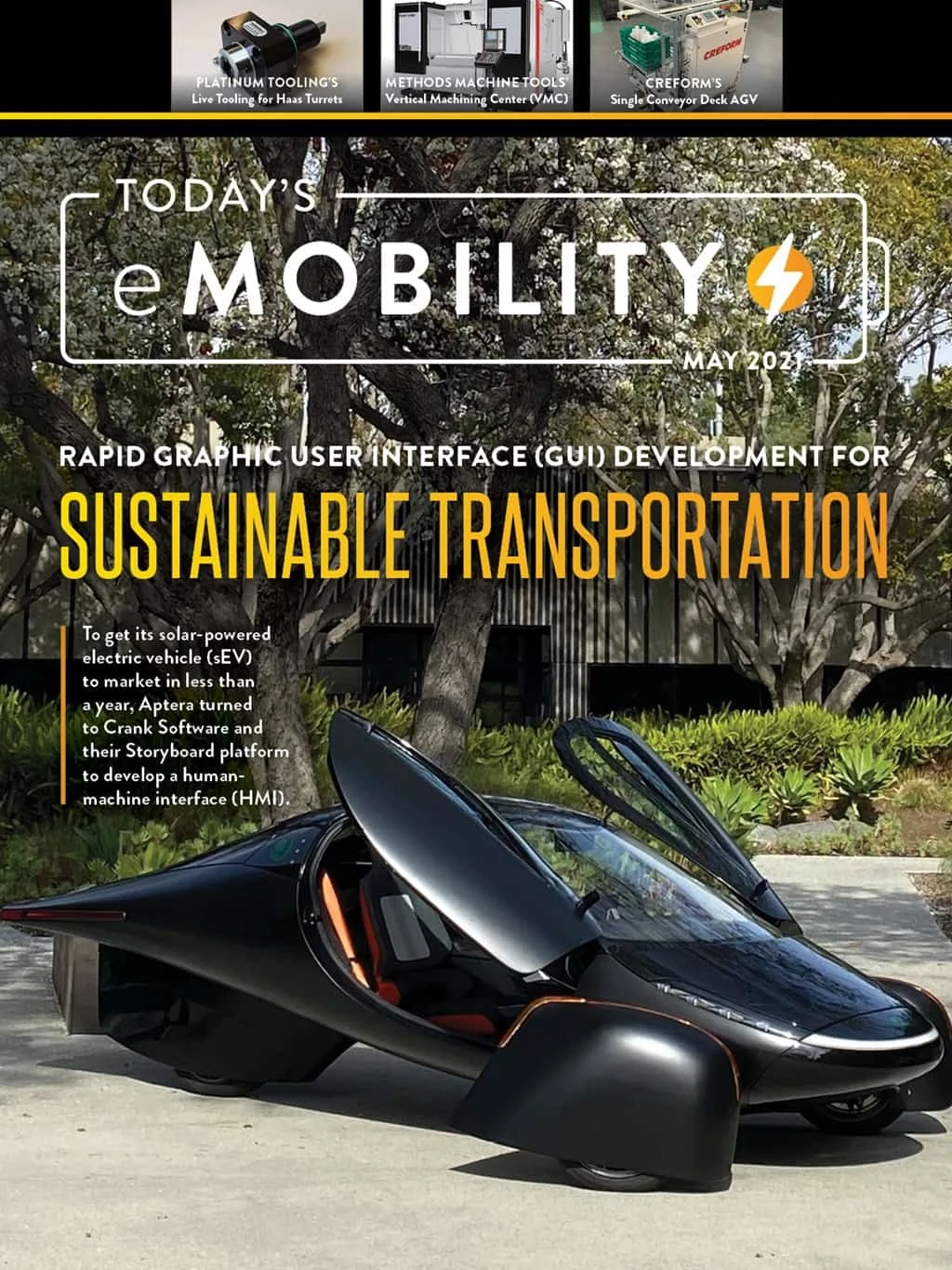

Explore the May 2021 Issue

Check out more from this issue and find your next story to read.

Latest from EV Design & Manufacturing

- Ford partners with Renault Group to expand European electric vehicle presence

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Wolfspeed’s silicon carbide components to power Toyota’s onboard EV charger systems

- Sunnen enhances e-commerce platform for precision honing equipment

- QuantumScape moves forward with automated battery cell pilot production line

- Dürr introduces next-generation low-pressure spray gun

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.