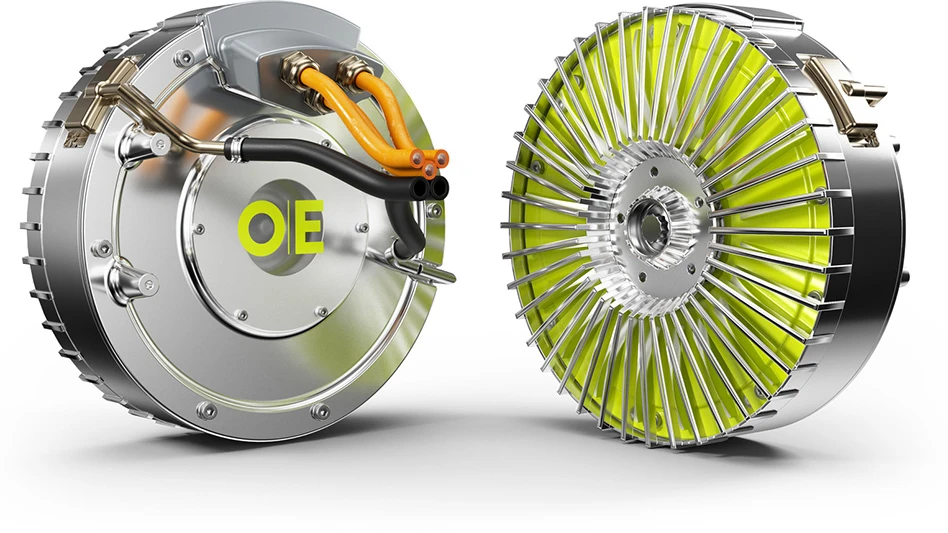

CREDIT: ORBIS ELECTRIC

Orbis Electric, a high-performance electric motor company, introduced HaloDrive, an advanced axial flux motor-generator built to power the next cycle of e-mobility. HaloDrive is designed around a modular four-part architecture with breakthrough innovations like an injection-molded plastic stator and a tunable gearset. This system delivers strong levels of performance, efficiency, and configurability – maintaining high torque and power density with greater thermal stability.

Designed for a variety of e-mobility applications, HaloDrive is highly versatile and can be deployed across commercial transportation, trucking fleets, stationary industrial power generation, and passenger vehicles as well as marine systems and aerospace platforms. The technology is an alternative to more common electric motors like permanent magnet synchronous motors (PMSM).

HaloDrive has been piloted by leading passenger vehicle OEMs for in-wheel propulsion systems and in heavy-duty trucking fleets as diesel-replacement generators. In these commercial applications, the electric motor is already delivering significant cost savings, including improving one customer’s fleet fuel efficiency by 61%.

Orbis Electric’s HaloDrive is engineered to fit within a wheel, reducing vehicle weight and improving range by 20%. When configured as a generator, the system can be easily installed in just three hours.

In the next cycle of e-mobility, businesses will drive the next stage of adoption of electric motors and generators in response to market demands for lower operational costs and higher energy and fuel efficiency. One of the emerging and practical opportunities is using electric motors as generators for electric transport refrigeration units (eTRU) configuration in commercial trucks. When replacing diesel-powered units, HaloDrive delivers up to 100% reduction in diesel refrigeration fuel consumption and emissions, and is 90% less expensive to operate. Installed on the driveshaft or an axle, the HaloDrive motor converts the truck’s braking energy into cost-saving electricity to power mobile refrigeration without dependency on plugging into the grid.

“Our vision with HaloDrive is to significantly advance how businesses transition to electrification by removing electric motor barriers such as deployment costs, material and manufacturability risks, and performance limitations,” says Chance Claxton, CEO of Orbis Electric. “With HaloDrive, we offer a high-performance axial flux motor that is not only highly efficient and powerful but also environmentally sustainable.”

Additional HaloDrive benefits and differentiators include:

- Torque density and power: Matching the torque of a V8 engine instantaneously, it delivers torque density of 100Nm/kg, outperforming conventional radial and axial flux designs.

- Modular versatility: Compact, configurable architecture supports multiple drivetrain positions (P2, P3, P4, P5), facilitating seamless integration and rapid scaling across various applications and form factors – without requiring structural modifications.

- Cost advantage: Provides up to 35% lower drivetrain costs compared to radial flux motors.

- Efficiency: Up to 97% operational efficiency, HaloDrive significantly reduces global electricity waste.

“Our approach with HaloDrive is and always has been about creating a motor that not only meets the immediate electrification needs across a range of industries, but is also compact and efficient enough to position businesses for future energy and sustainability standards,” says Marcus Hays, founder and CTO of Orbis Electric. “This is something our engineering team of EV, aerospace, fabrication, and environmental experts have spent years developing. We can achieve exceptional performance while also mitigating risks tied to rare earth materials, ensuring consistent availability and pricing stability.”

HaloDrive hits the U.S. market at a critical time, when transportation is the largest source of CO2 emissions globally, contributing 39% of U.S. emissions and 12% worldwide. And while electric-powered vehicles and generators are becoming more pervasive, one-third of the world’s electricity is consumed by inefficient electric motors, needlessly adding vast amounts of CO₂ to the atmosphere. Orbis Electric’s technology offers a scalable solution to reduce these emissions by as much as 1.4 billion metric tons of CO2.

HaloDrive is now available, with Orbis Electric actively seeking Tier 1 production partners – as well as OEMs, fleets, and industrial clients – to accelerate their electrification and sustainability goals.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?