Dassault Systèmes

“Consumers are charging toward electric vehicles.” That’s the headline from a recent Ernst & Young article discussing the company’s annual Mobility Consumer Index study and, lukewarm pun aside, the global consulting firm backs this claim with several eye-opening statistics. More than half of the study’s 13,000 respondents intending to buy a car over the next two years will choose an electric vehicle (EV) or hybrid vehicle and EV sales “will dominate those of other drivetrains by 2033, five years sooner than previously anticipated.”

Considering the monumental effort going into designing, testing, and manufacturing any new vehicle, let alone one based on rapidly emerging technologies, the question then becomes: what can automakers and battery manufacturers do to meet this accelerating consumer demand?

The answer is plenty, but only if they embrace another modern technology. It’s called software simulation using the virtual twin, and it’s speeding EV development in the same way the assembly line allowed workers to build a Model T in 90 minutes rather than 12 hours.

And yet, simulation goes much further than vehicle production. It makes EVs safer, quieter, and more affordable, while saving their manufacturers the missteps and do-overs accompanying traditional products launch. Studies show simulating with a virtual twin can cut battery development time by up to 50%, reduce electric drive development time and cost by 33%, and eliminate 25% or more of the vehicle’s aerodynamic drag.

Simulation and the virtual twin represent the clear path forward for any automaker, EV or otherwise, who wants to get to market faster and with less hassle than the other guys.

Peering at molecules

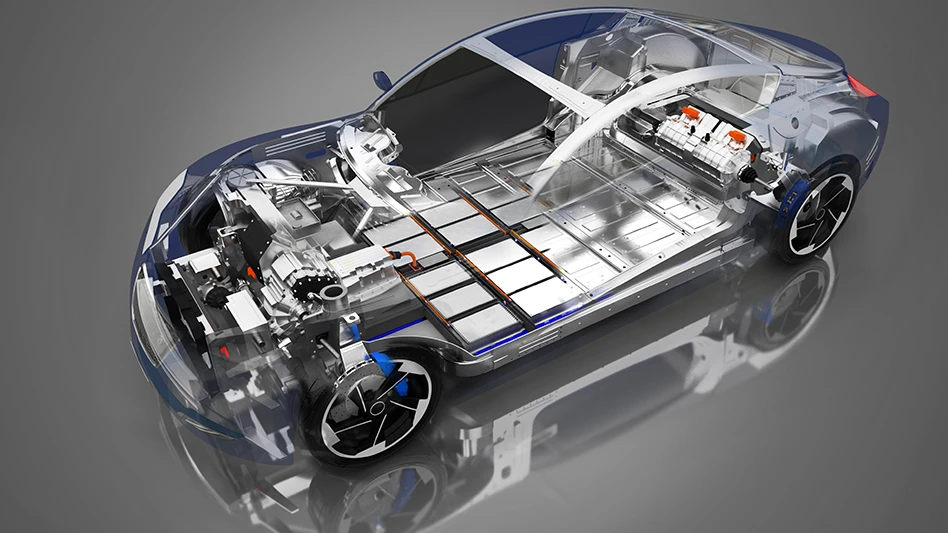

Consider the heart of any EV, its battery pack. The reason why EVs have taken so long to hit the road is their historically low range. That’s beginning to change as more manufacturers turn to simulation for battery development. Designers previously worked on critical components as much as they have on other vehicle system. They would put their best idea forward, build a prototype, test, and evaluate the results then repeat this lengthy, expensive process until reaching a reasonably effective design.

Software simulation eliminates the waste behind the design paradigm, shaving weeks or months between product iterations. It allows design engineers to get a virtual peek inside battery packs, modules, and cells, down to the atomic level if needed.

There’s no need for expensive engineering experts trying to determine what combination of anodes, cathodes, separators, and grids will deliver the best results. Designers can load up a simulation tool with digital versions of these and other battery components, plug in the expected operating parameters, and quickly run as many scenarios as needed to arrive at an optimized solution; one with the greatest energy density possible.

Taking it to the streets

Success extends beyond the initial design process. Developing a battery requires one to plan for summer heat, winter cold, and everything in between. Designers must anticipate the swelling occurring after thousands of charging cycles, and whether the battery will ignite after a vehicle crash. These and similar environmental factors must be weighed before the design can be considered sound.

Where designers once needed lengthy physical testing to evaluate prototypes under real-world conditions, simulation can replicate the conditions in a virtual world and in an accelerated, predictive manner, accurately illustrating how batteries will behave and perform years after they have left the production line.

Accurate simulation requires accurate inputs. Users must set up the proper framework, trade studies. The universe of data needed to perform the large-scale analytical processes is connected easily accessible to the software’s internal algorithms. It needs to be on a concurrent platform and its interrelationships clearly defined, a requirement cloud-based computing systems meet perfectly.

That brings us to the virtual twin, the means to connect all the data. It’s where the information required for complex engineering analyses sits on one platform, and the applications work on a common data set rather than being spread in little silos all over the company’s IT landscape.

Pulling it all together

Manufacturers can analyze the interactions between the products’ or system’s many components, whether it’s a commercial airliner, a packaging machine, or the complete EV and the various corner cases it’ll encounter in a virtual city. Taken to its maximum potential, the virtual twin is a comprehensive digital representation of an object that encompasses its physical counterpart’s data throughout its lifespan, streamlining its development and production while supporting ongoing improvement in a way never before imaginable.

In the case of an EV, the virtual twin can certainly provide critical insight during battery cell development utilizing modular level simulation tools original developed for the drug industry. Beyond that, however, the designer can then see how any changes in the cell chemistry will affect other aspects of the vehicle. It will guide the product engineer’s understanding of the most effective way to package the battery and, from there, how it will fit into the car’s structure.

Further, decisions about the battery might impact what motor is used, leading to questions over how much vibration and noise that motor will produce and whether the driver will hear it over the car’s infotainment system. For example, even the sound of the droplets of lubrication spinning inside the EV’s electric motor need to be simulated and minimized. These and countless other design considerations can be analyzed before the first piece of metal is ever ordered or the first production line set in place. Kudos to Henry Ford and all those who came after, but it is time to embrace the next phase of automotive design. Get simulating.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?