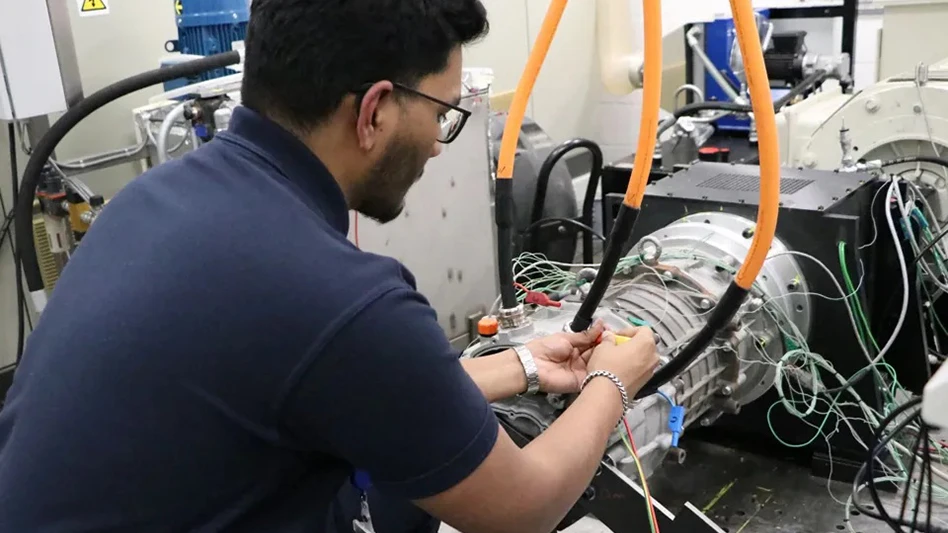

CREDIT: RICARDO

Ricardo, a global strategic, environmental, and engineering consulting company, has designed, developed, and tested a prototype electric propulsion module, Alumotor, an innovative rare earth metal free synchronous reluctance motor.

Alumotor was delivered within the Innovate UK’s funded consortium led by Ricardo to support sustainable mobility. It addresses issues related to the environmental impact of materials for electric motors.

Alumotor offers a low cost, robust, sustainable alternative to conventional copper wound permanent magnet machines. This synchronous reluctance motor is free from rare earth metals and critical raw materials, such as cobalt. It uses aluminum hairpin windings, and the machine is oil cooled to generate a power output of 214kW and maximum efficiency greater than 92%, making it suitable for light commercial vehicles and off-highway applications with full scalability to suit other applications.

“We are excited to be at the forefront of testing aluminum hairpin windings, and are achieving strong performance data that will support future go-to-market activities,” says Dr. Dragica Kostic-Perovic, Ricardo chief engineer responsible for the Alumotor project. “This is a significant development, showing true innovation, and supports our reputation as experts in the design and development of future sustainable technologies.”

Use of critical raw materials is of growing concern due to their environmental and social impacts. Ricardo’s experts work across the entire value chain to minimize the impact the use of such materials has, including in policy and strategy, product design, and circular economy applications.

The project was showcased at the Materials and Manufacturing Showcase 2025 in London, organized by UKRI, where the team had the opportunity to talk about the UK sustainable supply chain aspect and display the unit.

Latest from EV Design & Manufacturing

- Ford partners with Renault Group to expand European electric vehicle presence

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Wolfspeed’s silicon carbide components to power Toyota’s onboard EV charger systems

- Sunnen enhances e-commerce platform for precision honing equipment

- QuantumScape moves forward with automated battery cell pilot production line

- Dürr introduces next-generation low-pressure spray gun

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.