CREDIT: UCR/MIHRI OZKAN

Current battery management systems might report a car is 40% charged but drivers have to guess whether they can go 100km over hills with the heater running. Engineers at the University of California, Riverside want to take the guesswork out of it.

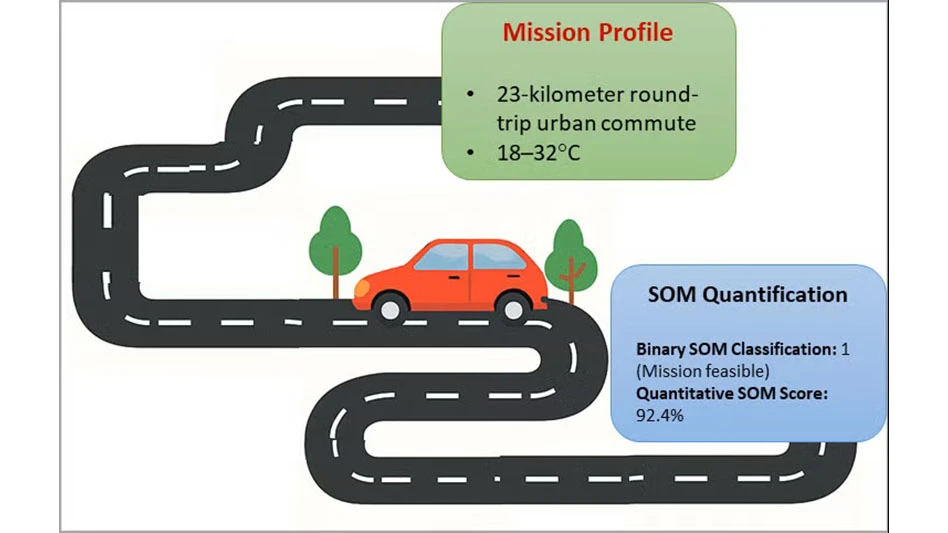

They’ve developed a new diagnostic metric called the State of Mission, or SOM, designed to answer a practical question: Can this battery, in its current state, safely and successfully power a specific task? SOM uses both battery data and environmental factors such as traffic patterns, elevation changes, or ambient temperature to generate real-time, task-specific predictions.

“SOM fills that gap,” says Mihri Ozkan, a UCR engineering professor who helped develop the system. “It’s a mission-aware measure that combines data and physics to predict whether the battery can complete a planned task under real-world conditions.”

Details of the system have been published in the journal iScience. What sets SOM apart is its hybrid approach. Unlike rigid physics equations that can’t adapt to changing scenarios, or machine learning models that generate results without explaining them, they’ve built a system that combines the strengths of both.

The model learns from how batteries charge, discharge, and heat up over time, but it also respects the laws of electrochemistry and thermodynamics. This dual intelligence lets it make reliable predictions even under stress, such as a sudden temperature drop or a steep uphill climb.

“By combining them, we get the best of both worlds: a model that learns flexibly from data but always stays grounded in physical reality,” says Cengiz Ozkan, a UCR engineering professor who co-led the research. “This makes the predictions not only more accurate but also more trustworthy.”

To test their framework, the team used publicly available battery datasets from NASA and Oxford University. These contained real-world usage patterns including charge and discharge cycles, temperature shifts, current and voltage data over time, and long-term performance trends.

Compared to traditional battery diagnostic methods, the model significantly reduced prediction errors by 0.018 volts for voltage, 1.37°C for temperature, and 2.42% for charge state.

Instead of a basic “percent charged” estimate, SOM offers a smarter, forward-looking output. It can tell a driver they can complete a planned route, but may need to recharge halfway, or that a drone flight is not feasible under certain wind conditions.

“It transforms abstract battery data into actionable decisions, improving safety, reliability, and planning for vehicles, drones, and any application where energy must be matched to a real-world task,” Mihri Ozkan says.

The model is still under development.

“Right now, the main limitation is computational complexity,” she says. “The framework demands more processing power than today’s lightweight, embedded battery management systems typically provide.”

Still, the researchers are optimistic. With further optimization, they expect the model could soon be used in electric vehicles, unmanned aerial systems, grid storage applications, and more.

Looking ahead, the team plans to test SOM in field environments and expand its capabilities to work with other battery chemistries such as sodium-ion, solid-state, or flow batteries.

“Our approach is designed to be generalizable,” Cengiz Ozkan says. “The same hybrid methodology can deliver mission-aware predictions that improve reliability, safety, and efficiency across a wide range of energy technologies from cars and drones to home battery systems and even space missions.”

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?