CREDIT: KALIBER MOTORS

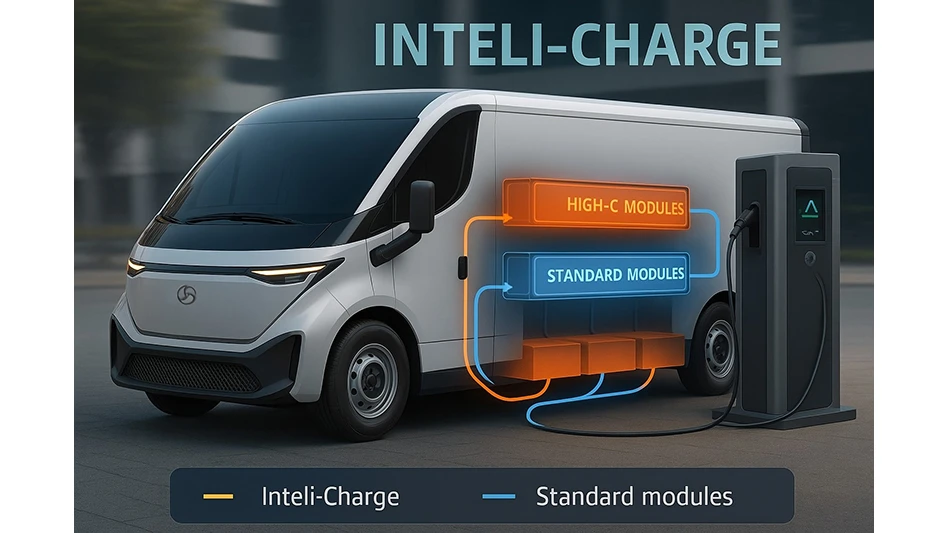

Kaliber Motors announces its latest proprietary breakthrough in energy architecture for electric vehicles (EVs) with the patenting of the Inteli-Charge Modular Hybrid Battery System. Engineered to accelerate fleet uptime and reduce vehicle charging downtime, Inteli-Charge combines high-C-rate lithium iron phosphate (LFP) modules with standard-capacity modules, all governed by an AI-enhanced predictive Battery Management System (BMS). Unlike conventional EV packs limited by uniform charge rates, Inteli-Charge decouples energy replenishment from full-pack cycling, enabling tactical, high-speed charge top-ups mid-route without added system cost. This hybrid solution delivers partial charge recovery in less than 10 minutes without compromising long-term battery health or cost-efficiency across fleet operations. Launching with the Kaliber Panther, the company’s last-mile, AI-integrated walk-in delivery platform, Inteli-Charge translates rapid mid-route ultra-fast charging into real-world uptime and a competitive operational edge.

“Vehicle uptime is the new battleground in fleet efficiency,” says Steven Braido, CEO of Kaliber Motors. “Inteli-Charge rewrites the playbook, not by increasing pack size or chasing peak charge speeds, but by sequencing and managing energy availability intelligently in both charge and discharge cycles. Our architecture gives operators the tactical edge they’ve been waiting for.”

Kaliber’s battery system uses a dual-class configuration of LFP cells, combining high-C-rate modules for ultra-fast top-offs with standard-capacity units designed for full-cycle recovery during idle periods. Kaliber’s proprietary Battery Management System (BMS) coordinates energy flow in real time, leveraging vehicle telemetry and AI-driven predictive logic to match power delivery to route demands and terrain.

While many manufacturers chase costly solid-state technologies or all-high-C-rate battery architectures, Kaliber delivers fast-charge performance without either trade-off. Solid-state systems often exceed $300 to $500 per kilowatt-hour and remain commercially immature, while full high-C-rate packs introduce unnecessary thermal strain and escalating cost challenges. Inteli-Charge sidesteps both extremes by leveraging mass-produced, stable LFP chemistry to balance charge velocity, durability, and system cost, delivering modules as low as $90 to $120/kWh and supporting large-fleet electrification without inflating system-level costs.

Beyond charging speed, Inteli-Charge introduces intelligent thermal management, hot-swappable module architecture for streamlined servicing, and cloud-connected diagnostics for fleet-wide optimization. Its fallback logic ensures uninterrupted energy on demanding routes, activating high-C modules precisely when needed and conserving peak power for surges and gradients. This multi-layered strategy translates directly to reduced ownership costs and extended battery lifespan across high-throughput commercial deployments.

Latest from EV Design & Manufacturing

- Ford partners with Renault Group to expand European electric vehicle presence

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Wolfspeed’s silicon carbide components to power Toyota’s onboard EV charger systems

- Sunnen enhances e-commerce platform for precision honing equipment

- QuantumScape moves forward with automated battery cell pilot production line

- Dürr introduces next-generation low-pressure spray gun

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.