CREDIT: INSTITUTE OF SCIENCE TOKYO

In today’s era of portable power and clean energy, lithium-ion batteries form the backbone of modern technology – powering everything from smartphones to electric vehicles (EVs). While demand for lithium-ion batteries continues to grow, so do concerns about their safety, environmental impact, and recyclability. Most lithium-ion batteries that rely on flammable organic solvents are energy-intensive to manufacture and require complicated recycling processes. These issues not only drive up costs but also pose serious safety and environmental risks – highlighting the need for safer and cleaner alternatives.

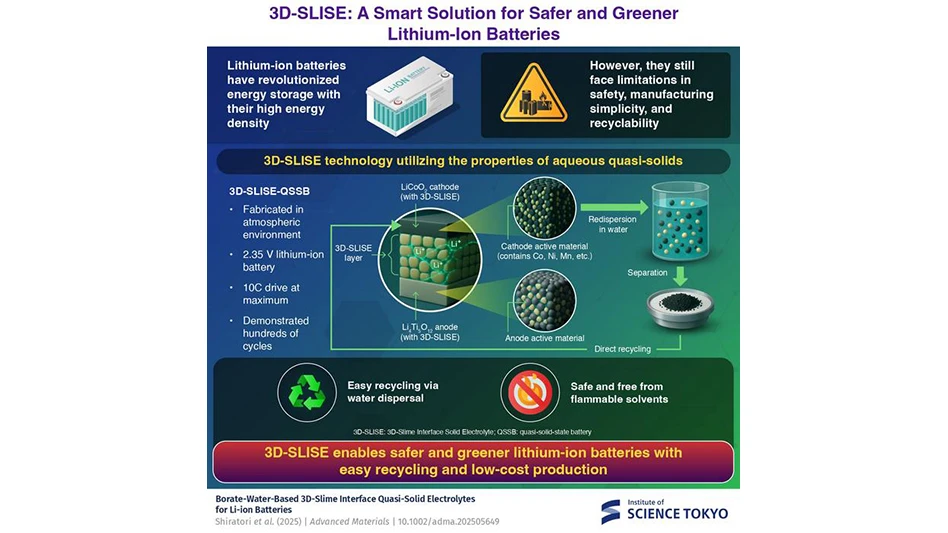

To address this challenge, a research team from Institute of Science Tokyo (Science Tokyo), Japan, led by Specially Appointed Professor Yosuke Shiratori and Associate Professor Shintaro Yasui from the Zero-Carbon Energy Research Institute, Science Tokyo, developed a new quasi-solid electrolyte called 3D-Slime Interface Quasi-Solid Electrolyte (3D-SLISE), which can transform battery manufacturing. With a simple borate-water matrix, the electrolyte supports the production of 2.35V lithium-ion batteries under standard air conditions. The detailed findings of the study are available online in the journal Advanced Materials.

“We aimed to create a battery system that is not only high-performing but also safe and easy to produce,” says Shiratori. “3D-SLISE eliminates the need for dry rooms, glove boxes, or high-temperature processing and offers a sustainable, energy-efficient approach.”

3D-SLISE was made by blending amorphous lithium tetraborate (a-Li₂B₄O₇) with a lithium salt (LiFSI), carboxymethyl cellulose, and water. This resulted in a slime-like interface that gives 3D ion conduction – allowing the lithium ions to move in all directions within the matrix. Based on the applications, two separate slurries of 3D-SLISE were made: Type E and Type S. Type E slurry was used to make the electrodes by mixing it with active electrode materials, including lithium cobalt (III) oxide (LiCoO₂) for the cathode and lithium titanate (Li₄Ti₅O₁₂) for the anode. Type S slurry was used as the quasi-solid electrolyte layer sandwiched between the electrodes in the battery assembly.

Notably, the slurries are dried naturally at room temperature, which is highly suitable for industrial processes. When the 3D-SLISE was integrated in the same manner as a standard all-solid-state battery, the resulting batteries showed a battery voltage of 2.35V under 1C rate conditions and delivered more than 400 charge/discharge cycles at 3C rates under normal room conditions. This means that the battery could be charged or discharged in just 1/3 hour (~20 minutes). Additionally, the quasi-solid electrolyte achieved a high ionic conductivity of 2.5 milli-siemens per centimeter and a low activation energy of 0.25 electron volts, indicating that the battery could operate efficiently at around room temperature. These results are comparable to those achieved in highly advanced aqueous systems.

While the battery performance was remarkable, 3D-SLISE also unlocks a further advantage of direct recycling. Since the electrolyte is water-based and contains no binders such as polyvinylidene di-fluoride, the active material can be recovered without harsh treatment by stripping the electrodes from used batteries and soaking them in water. This facilitates direct recovery of high-value materials from defective or used batteries, addressing both material scarcity and recycling inefficiency.

“Using this technology, it is possible to directly reclaim valuable elements like cobalt, contributing to a more sustainable and reliable supply of critical battery materials,” notes Yasui.

The study marks a significant milestone in sustainable batteries. Looking ahead, 3D-SLISE could be used in technologies ranging from such as portable electronics and stationary energy storage. With its unique combination of safety, recyclability, and low-impact processing, 3D-SLISE could help reduce battery production costs while minimizing environmental harm – moving us one step closer to a circular battery economy.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?