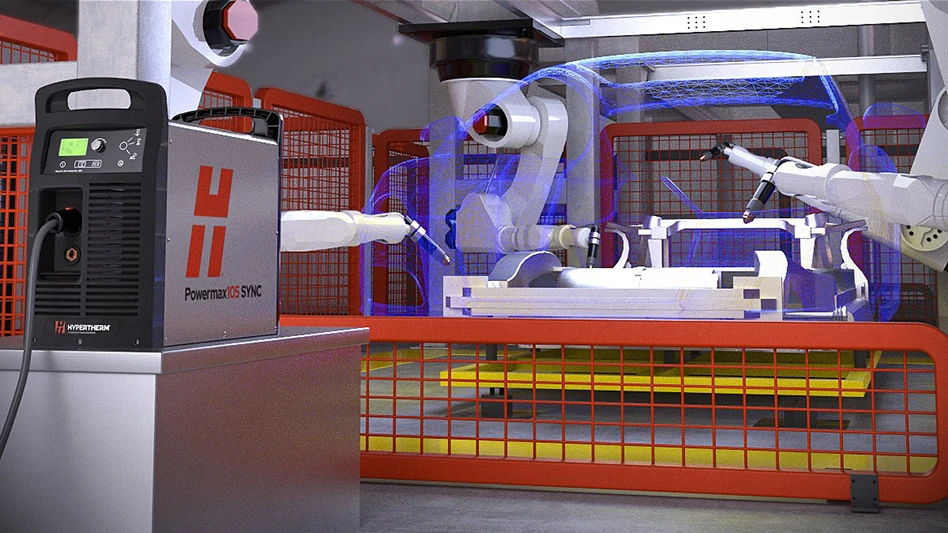

CREDIT: HYPERTHERM ASSOCIATES

The electric vehicle (EV) industry is under pressure to reduce vehicle weight, extend battery range, and scale production quickly, all while navigating rising costs and skilled labor shortages. To overcome these challenges, automakers must embrace innovative methods such as high-pressure die casting (also known as megacasting and gigacasting) as well as automation and robotics technology to boost productivity and profitability.

High-pressure die casting of large aluminum structural components is reshaping EV manufacturing. Body-in-white (BIW) castings simplify production by reducing the need for secondary welds and assembly points. At the same time, a high-pressure die casting manufacturing strategy requires a shift in finishing processes, particularly for the removal of gates, runners, and flash from large components.

Cobot plasma applications are an ideal solution for new finishing processes, offering numerous benefits to automotive manufacturers. Plasma is more efficient, safer, and a cost-effective alternative to traditional trimming methods.

Plasma cutting bests traditional trimming

For trimming large structural castings, plasma cutting is a game-changer compared to trim presses, sawing, and hammering.

While familiarity makes trim presses a comfortable choice for some companies, the cumbersome machines take up a hefty amount of square footage and come with financial drawbacks. They are expensive and require a large upfront cost. For smaller production facilities, this is a dealbreaker. Even for companies who can afford the initial capital investment, trim presses demand constant maintenance, which diminishes uptime and resources. Further, trim presses eliminate the option for a production line to be flexible. Reconfiguring a trim press is a slow and tedious process, which means downtime.

Plasma cutting, on the other hand, is a smaller capital investment – even when integrated with a cobot – easier to maintain, and much faster to adapt.

Aside from trim presses, saws and hammers have a deep tradition in degating. While easy to come by, they are messy and dangerous. Saws and hammers put operators at risk for injuries, and the process creates aluminum dust that is a fire hazard. To top it off, lubricants are often needed to reduce friction, meaning yet another step – cleaning – is added to the process.

Plasma cutting streamlines what saws and hammers can’t. Plasma is contact-free, keeps workers safe, cuts cleanly, and does not require extra cleanup.

Plasma and other modern applications

Fiber lasers are precise, but for large, uneven components produced through high-pressure die casting, they are not as cost-effective as plasma. With only 1mm of stand-off clearance for fiber laser, even the smallest variation in the workpiece can lead to material collisions and costly downtime.

Plasma cutting, with 6mm of stand-off, is better equipped to handle variances, avoid collisions, and deliver required results. Plasma technology’s extra clearance helps keep the production line running smoothly, reduces downtime, and ensures the final product meets quality standards.

© Hypertherm Associates | https://www.hyperthermassociates.com

Add the bot

To address the skilled labor shortage, manufacturers can also incorporate cobots for plasma applications. Specifically, Hypertherm’s Powermax105 SYNC plasma cutter, robotic torches, and Powermax cartridges easily integrate with a variety of cobots to form a single or multiple robotic trimming cell for small parts and large aluminum cast components.

Plasma is faster, safer, and more cost-effective for EV manufacturers who move to high-pressure die casting, megacasting, or gigacasting. For automakers who include automation via a cobot, productivity and profitability accelerate even more.

About the author: Russ Diefenbach is business team leader, Integrated Cutting Solutions at Hypertherm Associates.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?