CREDIT: STAR ASSEMBLY

Star Assembly, a wholly owned subsidiary of Mercedes-Benz AG, expanded its production portfolio and officially started the assembly of electric drive units for the all-new, fully electric Mercedes-Benz GLC. (provisional figures: energy consumption combined: 14.9 to 18.8kWh/100 km | CO₂ emissions combined: 0g/km | CO₂ class: A). The new production scopes in the area of electric vehicle (EV) components strengthen the strategic role of the plant in the Mercedes-Benz global production network and business strategy.

Sebeș is the second plant in the global production network to supply the Mercedes-Benz vehicle plants with electric drive units. The production site works closely with the German plant in Untertürkheim, the competence center for drive technologies responsible for producing the units for the new CLA and future models in the Top-End segment. With the assembly of electric drive units, Sebeș supplies key components to the production of the all-electric GLC, entering series production next year at the Mercedes-Benz plant in Bremen, Germany. Starting next year, Sebeș will also supply the Hungarian Mercedes-Benz plant in Kecskemét with electric drive units, where the new electric C-Class will roll off the production line. Romania’s Prime Minister Ilie Bolojan and further public officials visited the Star Assembly plant in Sebeș for the start of production ceremony.

"Producing the electric drive units for the new all-electric Mercedes-Benz GLC is an important milestone in the transformation of our plant and underlines the role of Sebeș in the global Mercedes-Benz production network,” says Jörg Burzer, member of the Board of Management of Mercedes-Benz Group AG, responsible for Production, Quality and Supply Chain Management. “Investments in the new production scopes enhance the flexibility and thus strengthen its future-readiness. I am proud of the highly engaged and skilled team that will continue its success story with this new high-tech-products.”

“Today we took an important step into the future of mobility. This achievement is the result of extensive cooperation, team dedication, flexibility, and expertise,” says Gheorghe Achim, CEO of Star Assembly & Star Transmission. “We are proud of our highly skilled workforce and grateful to the local community for their continued support. We also appreciate the authorities’ support for their role in this significant project. Together, these efforts position Sebeș as a vital hub in the global electrification strategy of Mercedes-Benz.”

Mercedes-Benz invested in a new facility, which spans more than 30,000m2 and integrates both assembly and logistics functions for electric drive unit production.

Digital and sustainable: High-tech assembly of electric drive units

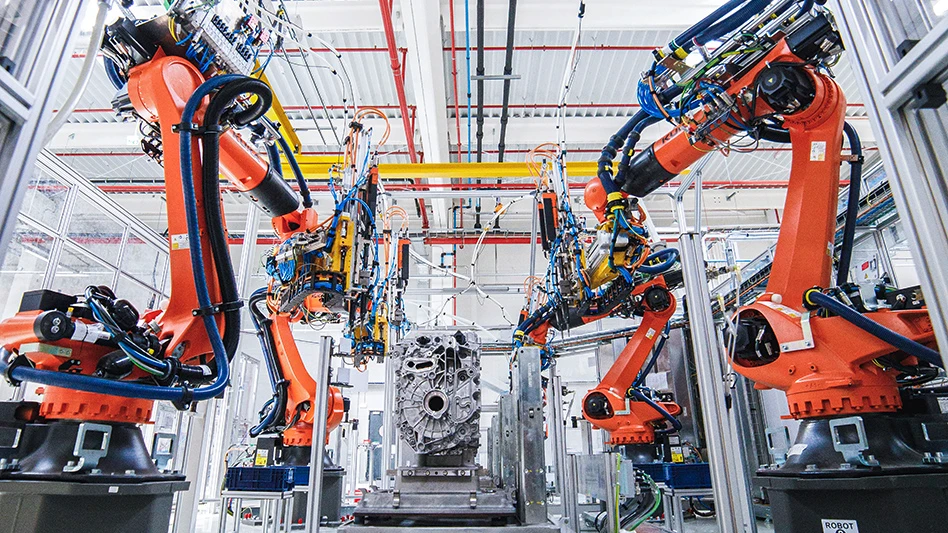

The electric drive unit for the new GLC was developed in-house at Mercedes-Benz. A drive unit essentially consists of three subsystems: an electric motor, power electronics, and the gear unit for power transmission. The assembly of these components into a complete system takes place at the Sebeș plant. The complete systems are supplied to the Bremen plant, where the GLC will enter series production next year.

The assembly of electric drive units is highly complex and requires numerous production steps. The assembly line covers around 15,000m2, extends around 1000 meters in length, and consists of more than 200 manual and automated processes. All operations at the new facility are staffed exclusively by employees reassigned from other areas of the Sebeș site. Their new roles are supported by an extensive qualification and retraining program, ensuring sustainable employment and long-term workforce development.

The plant is fully integrated into MO360, the Mercedes-Benz digital production ecosystem, and relates to the production network thanks to the MO360 Data Platform. Among other things, this ensures the complete traceability of every component, including all production data.

Production of the Sebeș site follows a sustainable concept: As is the case with all of the Mercedes-Benz production network's own locations, production in Sebeș operates in a net carbon-neutral manner and is powered by electricity from renewable sources. The installation of a photovoltaic system of up to 5MW is currently under review. The new production hall for the electric drive unit is supplied by a heat pump system.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?