CREDIT: SIEMENS

In a scene reminiscent of the many “perfect storms” in industrial design, Siemens has developed a fully integrated digital thread between its NX software suite of CAD and CAM products and the powerful SINUMERIK control technology in the emerging market of additive/subtractive manufacturing. This fusion, utilizing the company’s Create MyVirtual Machine and Run MyVirtual Machine digital twin technology, allows additive machine builders and users alike the ability to fully digitalize the machine build (including software systems, post processors, part programs, HMIs, and Edge devices), as well as machine commissioning and manufacturing process in a virtual world, long before the actual machine build or first part production begins.

With the adoption of large-scale additive technologies such as DED (laser-wire), WAAM, cold spray, material extrusion (FFF), and composites manufacturing (ATL/AFP) among others, the industrial world is beginning to see the value of 3D printing. Machine users are starting to transition from R&D/prototyping to end use manufacturing production. This can be seen in the industries of aerospace, automotive, oil-and-gas, heavy equipment, space, military, energy production, electronics manufacturing, construction, and more.

From the Siemens perspective, this sea change involves the creation of a full digital thread for each machine — allowing CAM toolpaths, generated by NX, to interface seamlessly with the virtual controller and run time code, complete with 3D machine kinematics, code execution, machine parameterization, visualization of material deposition and removal, and other real world characteristics that are so vital for the machine builder and end user to assess upfront.

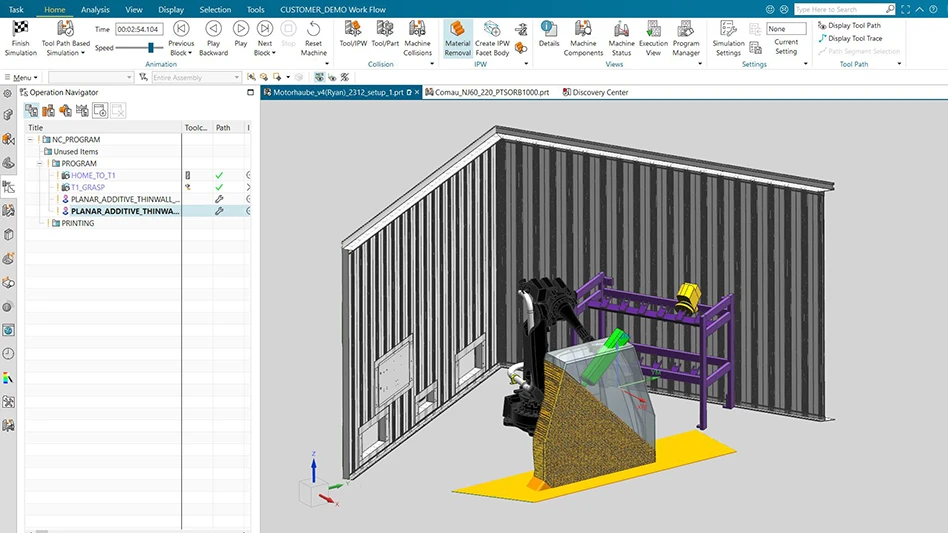

In one manufacturing example, a work cell is equipped with a SINUMERIK controlled 6-axis robot utilizing additive, subtractive, and probing end-effectors. The part, the hood of a vehicle, was designed in NX CAD using advanced tools for part optimization while also tested virtually in SIMCENTER 3D. Within the same platform, the mold design was generated from the final hood design. The toolpaths and post-processed NC code for additive, subtractive, and on-machine probing operations were created in NX CAM.

Launching the simulation environment brings up the digital twin of the SINUMERIK controller, allowing CNC machine data, PLC logic, and user cycles to play into the machine and 3D material simulation. This digital thread allows the programmer and machine operator to optimize toolpaths, prevent collisions and robot singularities, and analyze machine movements prior to the build; resulting in an additive pre-form that was machined down to required tolerances and finally probed for the quality inspection report.

Through the power of the Siemens SINUMERIK control, additive and subtractive operations, robotic movements, and end-effector process control are all commanded from the single controller. Combining CNC technology with the flexibility of robot arms opens a new realm of possibilities that were not possible with regular robot controllers.

The advantage of the synergy between the company’s NX software and SINUMERIK hardware affords the machine builder and user the highest fidelity part program time estimate and machine movement, possible. The inherent flexibility of NX to simulate hybrid scenarios combines with the SINUMERIK virtual controller, providing a comprehensive look at the machine’s characteristics and the production process. This is extremely useful for manufacturers in many aspects of their businesses, from material acquisition to construction time, production scheduling, labor costs, and more.

This digital thread evolution represents a central building block of a truly closed loop control scenario, especially with the inclusion of the robot in the NX and CNC portfolios of operational possibilities. Probing operations through the connections of Siemens hardware and software allow continuous manufacturing operations when bringing together additive, subtractive, and various metrological, machine vision, or NDE technologies.

In use for this application, NX delivers design, simulation, and manufacturing solutions that enable companies to realize the value of the digital twin. Simcenter 3D is a comprehensive, fully integrated CAE solution which allows designers to test the part performance and help with novel design features through the freedom of additive manufacturing.

This powerful Siemens technology significantly expands the ecosystem for machine builders and users alike as they utilize the enhanced technologies and manufacturing possibilities for their companies to combine the additive and subtractive worlds.

Latest from EV Design & Manufacturing

- Ford partners with Renault Group to expand European electric vehicle presence

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Wolfspeed’s silicon carbide components to power Toyota’s onboard EV charger systems

- Sunnen enhances e-commerce platform for precision honing equipment

- QuantumScape moves forward with automated battery cell pilot production line

- Dürr introduces next-generation low-pressure spray gun

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.