Volume Graphics

Owners of battery electric vehicles (BEVs) and hybrid cars might be alarmed over recent news reports of recalls of plug-in hybrids over fire risk, cars bursting into flames after a crash, and batteries being pulled off the market. In many cases the culprit remains a mystery, attributed to manufacturing defects or "unknown causes."

And yet, these fire-related events may not occur as frequently as headlines suggest: Forbes magazine reports that, in 2022, insurance referral service provider AutoinsuranceEZ analyzed data from the U.S. National Transportation Safety Board (NSTB) and concluded that BEVs were less prone to catch fire than hybrids or internal combustion engines (ICEs). But other sources quoted in the article noted that the sample sizes were small and the data insufficient to accurately compare BEV safety. Still, other sources noted that Lithium-ion battery fires are nevertheless more difficult to put out than conventional ones, because the energy release during the exotherm of the electrolyte takes a lot of cooling to extinguish.

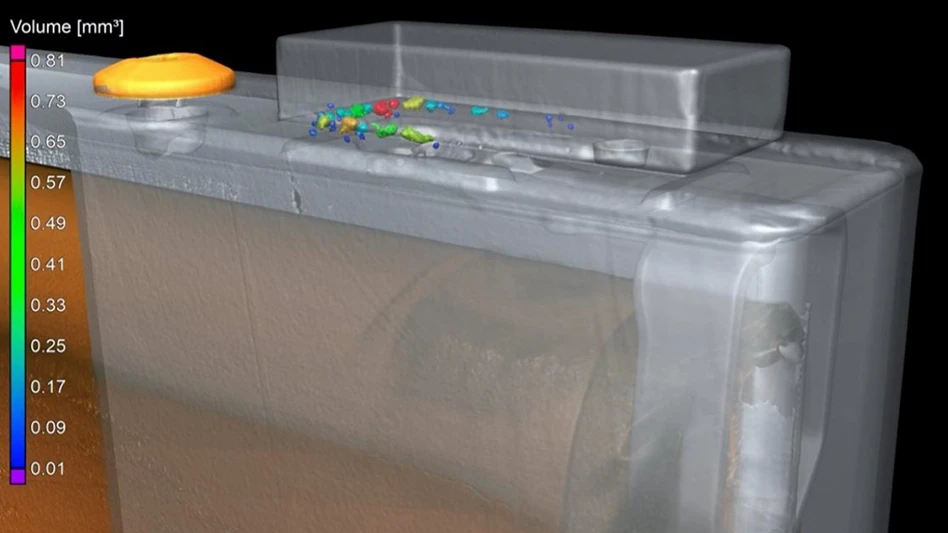

of the image (note mm scale) indicate anode

overhang, a structure that is crucial to battery

performance and safety.

Of course, it’s already known that Lithium-ion batteries in many other, non-automotive products have had a history of issues with fire. So it’s certainly desirable for vehicles of every kind to be as safe as possible, regardless of what powers them.

Laser-focused on the details

This is why automotive battery designers are intently focused on understanding the complex chemistry and construction of these increasingly necessary power sources. The same can be said for their manufacturers, who must continuously monitor production processes to ensure that battery cells, packs, and modules adhere to specifications.

But what is it about Lithium-ion batteries that makes them prone to catching fire? And perhaps more relevant to their owners (despite the headlines) is the vehicle’s driving range, time needed to recharge, and long-term battery performance. Each of these must be optimized and any safety risks mitigated before the BEV revolution can reach maximum cruising speed.

Industrial Computed Tomography, more commonly referred to as CT scanning, has begun playing a significant role in all these endeavors. So has the advanced software that makes sense of CT-generated images, allowing users to measure voids and particle sizes within electrode active material during the research and development phase, detect delamination and contamination during cell manufacturing, analyze electrical connections and electrolyte fill levels, and provide many other quality-assurance functions that were once impractical or even impossible to perform.

software allows the user to simply “paint” the

structures they want to segment within a dataset

(left) and Paint & Segment will automatically

complete the task (right).

Checking the boxes of manufacturing steps

Three main types of batteries exist—pouch, prismatic, and cylindrical. Whatever the shape, the data from a CT scan of the battery can be analyzed with sophisticated software at any point during its entire lifecycle, which begins with electrode manufacturing. This involves spraying a slurry of lithium, nickel, cobalt, and other metals onto a foil made of aluminum (for the cathode) or carbon onto copper (the anode), then rolling or “calendaring” the resultant product into thin sheets that are then made into cells—the building blocks of any lithium-ion battery.

The density and distribution of individual particles is critical to efficient ion storage, but since these tiny bits of metal—the active material—are best measured in microns, nano-CT-scanning with its ability to “see” even the smallest of features is the most effective inspection method available.

Advanced imaging and analysis software converts a series of two-dimensional, black-and-white CT-scanned images into dimensionally accurate 3D models of the object. Researchers then use these to determine particle size and distribution. They can measure variation in the layer thickness, spot voids, and detect contamination. And once the coated foils are cut to size, rolled, or stacked, and assembled into the cells that make up the battery pack, they can look for inclusions, thought to be the main cause of battery fires.

Inclusions form when molten metal penetrates the battery pack during welding, or when small bits of foil from the cutting process make their way into the cell. However, they get there, these particles can damage the thin layer of plastic that keeps the battery’s anodes and cathodes separate from one another. And even if there is no direct harm at the time of manufacturing, mechanical friction over the course of the battery’s lifetime can cause the separator to fail, possibly leading to a thermal runaway. Detecting inclusions at the time of manufacturing is therefore crucial and is also why many used batteries are CT-scanned upon removal from a vehicle, to determine whether they might go on to a “second life” in stationary charging stations or for domestic energy storage.

inclusions that could puncture the plastic separators

in battery cells and potentially cause a runaway fire.

CT scanning and analysis finds other defects as well. Porosity in the weld lines is not likely to cause a fire, but it can lead to leakage. Here, snow and rainwater can seep into the battery over time. The electrolyte within then reacts to form hydrofluoric acid, a highly corrosive gas that irritates the eyes, nose, and respiratory tract in humans.

There’s also layer delamination to consider, a phenomenon that reduces battery capacity. And “anode overhang,” the small but necessary height differential between anode and cathode that’s critical to battery safety—without it, lithium crystals can form on electrode edges, eventually growing large enough to puncture the separator and cause a runaway.

Beyond the black and white

Although CT scanning is the only metrology tool able to non-destructively inspect for these and countless other defects and conditions, there’s one caveat: analysis of the resulting data is complex and requires advanced software analysis to interpret the images and identify various features.

These software tools can dramatically simplify the inspection process, allowing even non-expert users to leverage CT scanning to its fullest capability. This is especially true for battery researchers, designers, and manufacturers, who have a host of application-specific tools at their disposal.

For example, VGSTUDIO MAX from Volume Graphics allows operators to identify those metallic inclusions that can damage the electrode separators. They can verify that anode overlap is sufficient to prevent short-circuits and do so at any point in the manufacturing process, even once the battery pack has been completely assembled. More importantly to the future of BEVs—and indeed any electromechanical device that requires a battery—is the ability to optimize existing designs, evaluate new materials, and possibly develop storage technologies that would completely revolutionize the industry.

New software capabilities expand analysis scope

Recent developments are making this last possibility more likely. Volume Graphics has introduced several new tools, such as an anode overhang analysis function that provides enhanced visualization and reporting for this common measurement. There's also a new auto-segmentation feature that allows the operator to digitally "paint" a representative section of a structure they wish to analyze, after which the software will identify and mark any like structures.

One of the most exciting of these is a machine-learning function that automates much of the effort that comes with image processing. Customers can train the software on which part-features or details to look for and what to do with them when found. For instance, the computer could reference previously saved models in the Paint & Segment function just described, thus automating the segmentation process to detect undesired foreign particles within a battery cell.

Given the growing demand in the e-mobility sector, such capabilities will quickly go from nice-to-haves to must-haves. Most countries aim to phase out internal combustion engines by 2040 at the latest (and some have far more aggressive plans), which means that hundreds of factories worldwide will be called upon to produce safe, efficient, and cost-effective batteries in quantities never seen.

Latest from EV Design & Manufacturing

- Ford partners with Renault Group to expand European electric vehicle presence

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Wolfspeed’s silicon carbide components to power Toyota’s onboard EV charger systems

- Sunnen enhances e-commerce platform for precision honing equipment

- QuantumScape moves forward with automated battery cell pilot production line

- Dürr introduces next-generation low-pressure spray gun

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.