Photo courtesy of Research and Markets

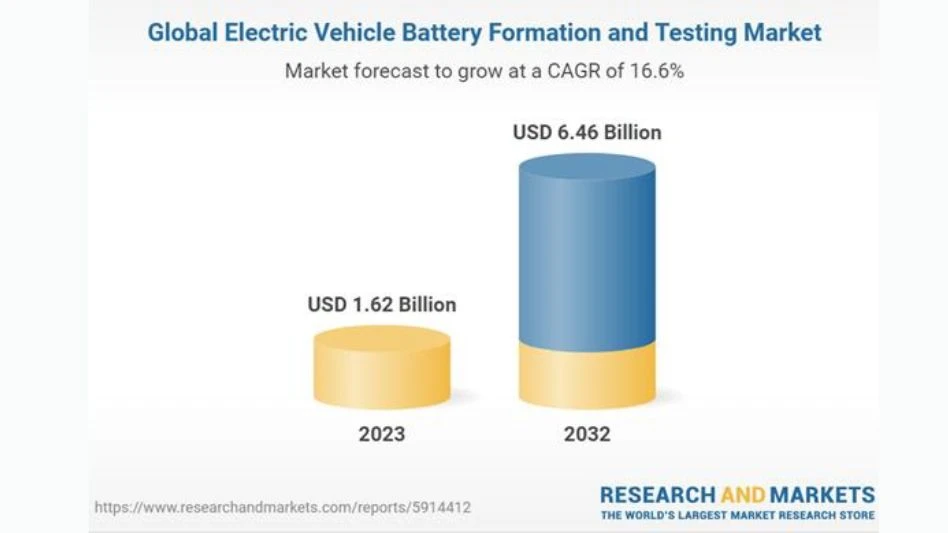

According to Research and Markets, the electric vehicle battery formation and testing market was valued at $1.42 billion in 2022, and it is expected to grow at a CAGR of 16.59% and reach $6.46 billion by 2032. The growth in the electric vehicle battery formation and testing market is expected to be driven by growing demand for EVs and the need to ensure the safety, reliability, and performance of EV batteries. As EV adoption accelerates, battery manufacturers are under pressure to produce high-quality batteries that meet stringent safety standards.

The electric vehicle battery formation and testing market is currently in the growth stage of its life cycle. This means that the market is experiencing rapid growth, driven by several factors, including:

Increasing demand for EVs: The demand for EVs is growing rapidly as governments around the world implement policies to reduce greenhouse gas emissions from transportation. This is leading to increased production of EVs, which in turn drives demand for EV battery formation and testing services.

Need for advanced technology: As battery technology continues to evolve, the need for advanced battery formation and testing equipment and services is also growing. This is because newer battery chemistries and technologies require more sophisticated testing procedures to ensure their safety and reliability.

Regulatory requirements: Governments are increasingly imposing stringent safety and performance standards on EV batteries. This is leading to increased demand for battery formation and testing services that can help manufacturers comply with these regulations.

The growth stage of the electric vehicle battery formation and testing market is expected to continue for several years as EV adoption accelerates and battery technology continues to evolve. However, as the market matures, it is likely to enter the consolidation stage, where competition among testing service providers intensifies and pricing pressure increases.

Testing to dominate the EV battery formation market

Electric vehicle batteries require rigorous safety checks for safe installation and integration with systems. A wide range of testing is required after the actual battery formation process, right from a charging infrastructure to the battery of the vehicle, and to make sure the battery is in line with the industry standards. Therefore, testing is the largest application within the electric vehicle battery formation and testing market and is anticipated to maintain its dominance during the forecast period 2023-2033.

Lithium-Ion to dominate the EV battery market

Lithium-ion batteries lead the electric vehicle battery formation and testing market due to their superior energy density, which enables longer ranges without significant increases in weight or size. They are lighter, more compact, and offer better performance and charge/discharge efficiency than nickel-metal hydride batteries. Lithium-ion batteries also boast a longer lifespan, contributing to the overall durability and cost-effectiveness of electric vehicles. Ongoing advancements in lithium-ion technology, including improvements in safety and cost, further solidify their position as the preferred choice for electric vehicle manufacturers.

In-house to dominate the EV battery market

The in-house sourcing type is anticipated to attain the biggest market share over the forecast period 2023-2032 as a result of businesses' experience in carrying out in-house battery testing activities under total control. Additionally, in-house sourcing's cost-effective assessment strategy guarantees higher levels of customer satisfaction and aids government organizations in being more productive.

Cloud-based segment to garner the highest growth in the EV market

Cloud-based testing is poised to lead the electric vehicle battery formation and testing market over on-premises testing due to several key advantages. Cloud-based testing offers scalability, allowing manufacturers to access and utilize testing resources dynamically based on demand, thereby optimizing efficiency and reducing costs. The flexibility and accessibility of cloud-based solutions enable collaboration among geographically dispersed teams and facilitate real-time data sharing. Additionally, cloud platforms provide advanced analytics and machine learning capabilities, enhancing the analysis of complex battery testing data and aiding in predictive maintenance.

Mechanical tests to dominate the EV battery market

As electric vehicle batteries need to withstand various stresses during operation, mechanical testing assesses factors such as vibration, impact, and structural durability. These tests are fundamental for mitigating the risk of physical damage or failure in real-world driving conditions. While thermal, electrical, chemical, and performance tests are vital for evaluating specific functional aspects and efficiency, mechanical tests serve as a foundational step in guaranteeing the overall robustness and reliability of electric vehicle batteries. As safety remains a top priority, a comprehensive approach that emphasizes mechanical testing is essential to instill confidence in the durability of electric vehicle batteries, especially in a market where reliability and safety are paramount concerns for both manufacturers and consumers. However, over the forecast period 2023 to 2032, thermal testing is expected to lead the electric vehicle battery formation and testing market.

China to dominate the EV battery market

China leads the electric vehicle battery formation and testing market for several reasons. The country has strategically positioned itself as a global leader in electric mobility, fostering an environment conducive to production. Government policies and incentives, including subsidies and regulations promoting electric vehicle adoption, have accelerated the growth of the electric vehicle market in China. Additionally, robust investment in research and development, coupled with significant advancements in battery technology, has allowed regional companies to stay ahead in the development of electric vehicle batteries. The presence of a well-established manufacturing infrastructure and a large domestic market for electric vehicles contributes to China's leadership in the electric vehicle battery formation and testing market.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?