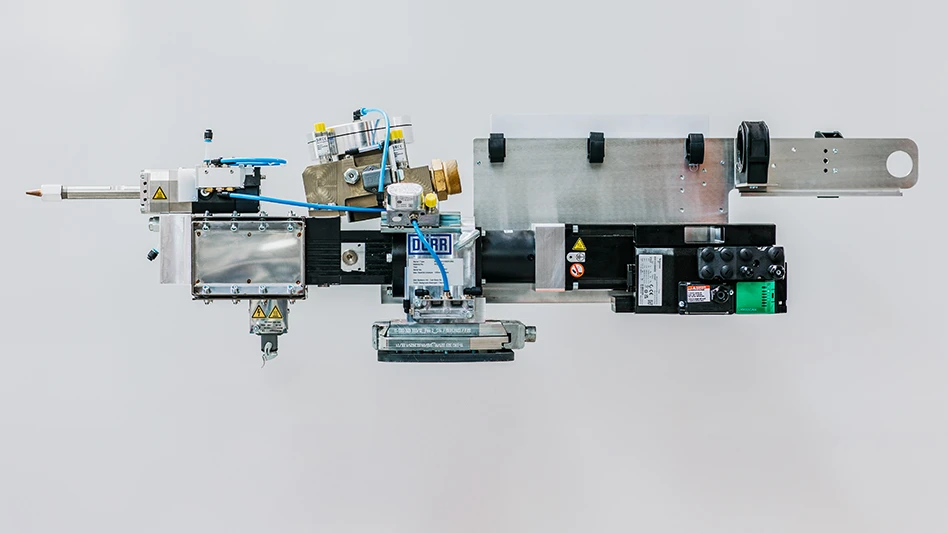

CREDIT: DURR

Batteries are arguably the most mysterious component of electric vehicles (EVs). They’re highly complex, with intricate assemblies and precise chemistry. Often left out of the more high-profile discussions on battery composition are the adhesives and sealants that hold everything together – however, they’re vital for battery safety and performance.

The Dürr Group specializes in industrial manufacturing solutions including adhesives and application technology for battery systems. Sebastian Gries, senior sales manager Automotive Gluing Systems, answers a few questions about these critical materials.

Q. What role do adhesives and sealants play in the manufacture of electric vehicle batteries?

A. The process of bonding and sealing the cell modules and battery packs plays a crucial role, as the precise application of adhesives and sealants significantly contributes to battery safety and longevity. Vulnerable battery cells are at risk of damage from stone impacts, vibrations, and heat buildup, as well as from moisture and dirt. Sealants are utilized to seal the gaskets of the battery pack, aiming to prevent moisture incursion. Furthermore, they are required to survive collisions without sustaining damage and to withstand a fire until the vehicle occupants have moved to a safe distance. The primary function of thermal adhesives is to ensure effective thermal management of the battery, thereby extending its lifespan and preventing thermal runaway.

Q. What types of materials are used to bond and seal the various battery components?

A. In the field of battery dispensing processes, Dürr has successfully developed solutions for highly abrasive adhesives, two-component materials, and hot melts with different viscosities. Thermally conductive adhesives play a critical role in the bonding of cells and modules to cooling devices. This ensures effective heat transmission, safeguarding the battery's integrity, and maximizing its longevity. Structural adhesives are utilized to secure the battery pack's structural integrity, while sealants are employed to ensure the closure of the battery pack, its cover, and screwheads.

Q. How are these materials applied?

A. Depending on the shape of the components, the application pattern, and the adhesive, a variety of different application processes are used to bond and seal the individual components of a battery cell. The structural adhesive that bonds the assemblies together to stabilize the battery packs is applied using an extrusion process. Dürr uses its EcoShot Meter dosing systems for even, uninterrupted adhesive application.

By contrast, the fire-retardant pastes designed to prevent flame penetration in the event of a fire are sprayed onto the aluminum cover using a two-component spraying process. The same application process is used for the sealant that seals the heads of the bolts fastening the cover in place. The nozzle system specially developed by Dürr for this purpose ensures a consistent spray pattern. An injection process is also used to fill cavities, for example, between the cell modules and the cooling system. This is known as gap filling.

Dürr offers a wide-ranging portfolio to fulfill all battery production requirements, including various types of nozzles for different application patterns and modular shot meters for 1K, 2K, and hot melt. Dürr’s gluing products are particularly robust and of high quality, capable of conveying dense, abrasive materials without damaging pumps and dispensers, thanks to the stainless-steel material used and special coatings. Furthermore, the system is flexible, accommodating different viscosities, materials, and processes (1K to 2K) with products designed for each specific material.

Q. How can EV battery manufacturers keep up with rapidly changing requirements?

A. Manufacturers must establish flexible production systems that enable them to adapt their products to new developments in a relatively short period of time. The following products from Dürr serve as exemplars of this flexibility.

It’s possible to carry out applications using a single-piston dispenser; however, this method has the disadvantage of necessitating the refilling of adhesive or sealant after each process, which results in increased processing time. To address this, Dürr utilizes continuous dosing in its modular system. This objective can be achieved through two distinct methods.

In the case of two-component applications, two EcoShot Meters are integrated into a tandem configuration. This eliminates the need for refilling, allowing cycle times to be maintained and reducing investment costs by consolidating tasks into a single work stage.

The EcoMeter SP provides the same advantages for single-component applications. The robot's payload capacity for single-component continuous dosing remains constant, equivalent to that of a single EcoShot Meter, ensuring consistent performance and operational reliability. Dürr's modular design facilitates the direct retrofitting of each solution described into the existing system.

Sebastian Gries, senior sales manager Automotive Gluing Systems at Dürr System AG, is a graduate mechanical engineer and has been working in the field of gluing technology for more than ten years. He has been with Dürr for seven years and has held several positions here, including project manager and product manager for gluing applications. Furthermore, Gries is a member of the battery production working group of the German Machinery and Equipment Manufacturers Association (VDMA).

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?