Siemens Digital Industries Software

Today, most consumers are familiar with the concept of a fully autonomous vehicle (AV) that can deftly navigate complex driving environments without any human input. Such depictions, present in many forms of popular media, offer a general view of the potential capabilities and benefits of AV technology.

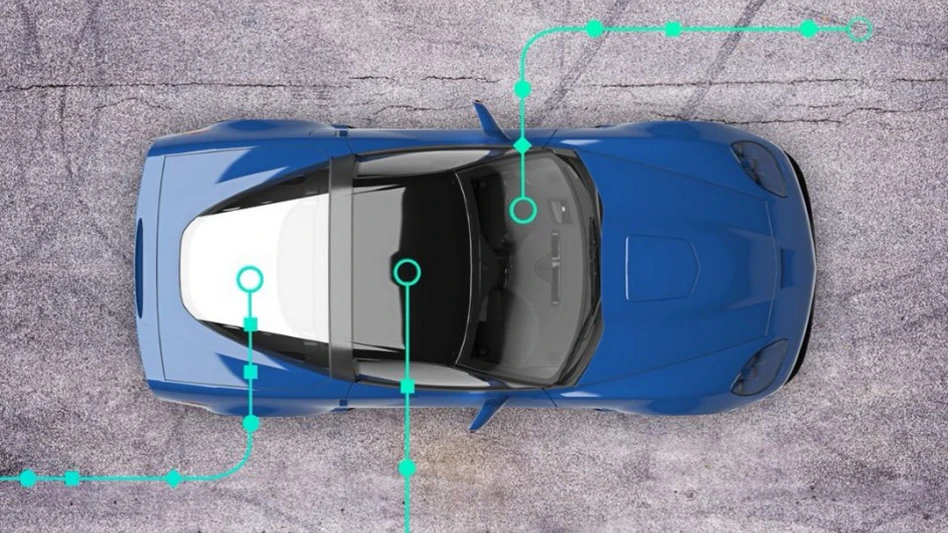

The realization of this potential future depends on the ability of an AV to gather and process immense amounts of data from various systems, and the details of how an AV might achieve this task are gradually coming into focus. It is already clear that AVs will require a significant amount of advanced electronics hardware to operate. Specific numbers may range, but many experts expect an autonomous vehicle will require approximately 30 advanced sensors and immense processing capabilities to safely navigate a dynamic driving environment (figure 1).

Figure 1: Autonomous vehicles will rely on dozens of advanced sensors, each generating dense data streams, to enable the vehicle to perceive its environment.

Beyond electronics and software, a constellation of advanced technologies and engineering domains must work seamlessly together to achieve true self-driving capabilities. This includes mechanical, electrical, and electronic systems as well as embedded software, artificial intelligence and machine learning, and communications networks all operating in harmony to deliver self-driving functionality. In an AV, these domains intersect to a greater degree than they have previously, ensuring that no system within the vehicle is truly independent.

A lane-keep assist system, for example, requires sensors, processors, and software to perceive road lines and calculate vehicle trajectory before activating mechatronic components in the steering system to exert control over the vehicle.

Yet, even the most advanced systems available today only achieve level 3 self-driving capabilities. These systems require the human driver to take control under certain circumstances. A level 4 system exerts total control over the vehicle, but only within its specified operational conditions. Level 5, the pinnacle of vehicle autonomy, delivers total control in all conditions, on all road types, and with no human supervision required.

As companies continue to climb the ladder of autonomy, they will face an exponential increase in complexity at each rung on the ladder as additional systems are integrated, more data is passed through vehicle networks, and computational and electrical power demands grow. How do companies absorb and manage such a huge increase in complexity, power, and data within the vehicle platform? And what implications do the requirements of an AV have on the design and development of these sensor and processing devices?

Design Challenge: Integrating advanced electronics into automotive platforms

The electronics systems that will enable future self-driving systems will be a diverse mix of sensors and powerful processing devices all connected by high-speed data networks. The appropriate mix and location of these devices in the vehicle body is an important consideration and provides opportunities for design exploration and optimization.

An autonomous vehicle will likely depend on several sensor types to construct a complete picture of the driving environment and both short and long ranges. Different sensor types will also be needed to enable tasks like object recognition that will drive decision making by the artificial intelligence (AI) algorithms taking in data from around the vehicle. Common sensor types include cameras, ultrasonic sensors, radar, and lidar, each of which offer unique benefits and drawbacks to enabling the vehicle to perceive its surroundings.

Figure 2: AVs will likely require multiple sensor types and even connections with external systems, such as smart infrastructure, to enable complete perception around the vehicle. (credit: Siemens)

A critical challenge will be the integration of various modes of perception and processing into a cohesive system that enables immediate reactions to external conditions without fault or delay. This may even include data streams from outside the vehicle, such as from smart infrastructure and smart city systems (figure 2). As the amount and speed with which data is generated by these sensor systems increases, the capabilities of an autonomous system will ultimately come down to the processing power achieved by its computational units and the capabilities of the AI algorithms.

Custom chips offer best performance

Computational power translates to faster data analysis and thus faster and more accurate decision making by self-driving algorithms. As a result, companies traditionally focused on building cars are now very interested (and invested) in the development of powerful integrated circuit (IC) chips. These chips will be asked to support artificial intelligence algorithms as they churn through multiple streams of rich sensor data in real time to support nearly instantaneous perception and reaction. The development of these advanced silicon devices is among the most challenging and critical tasks facing those in pursuit of autonomy.

Given the complexity and challenge of creating such chips, it begs questioning why car manufacturers are wading into custom IC design. There are two major benefits. First, embarking on custom silicon development gives automakers more control over how the chip is designed and optimized to fit the needs of the vehicle platform. Second, the chip design process can be integrated into the automaker’s development ecosystem, ensuring full traceability and connectivity from the vehicle architecture to the chip design and back to specific requirements. The added control and traceability will unlock greater chip performance, efficiency, and better integration into the electrical and electronic systems of the vehicle.

Digitalization empowers advanced vehicle design

On the path to self-driving vehicles, the automotive industry faces its most daunting design and engineering task. Engineering teams must account for hundreds of thousands of interactions between increasingly complex vehicle systems while also navigating a shift in the very nature of automotive development. In addition, these teams must ensure that their self-driving systems can safely navigate driving environments by gathering and processing terabytes of data every second from dozens of sensors dispersed around the vehicle.

How can companies overcome these hurdles to continue down the path to full autonomy? It starts with a digital transformation of the vehicle design process. Digital transformation enables companies to adopt a new approach to mobility solution development and engineering, linking their entire lifecycle through a digital backbone that enables information to flow throughout the organization. Even partner companies can be incorporated securely into the digital backbone, ensuring faster and easier collaboration between organizations, and supporting accountability to overall goals.

Digitalization offers key benefits to automotive OEMs developing the vehicles of tomorrow. First, it establishes connections between previously siloed teams or departments and the entire automotive supply chain, eliminating data flow problems and reducing mistakes or miscommunications. New connections and increased collaboration also ensure that mistakes, inconsistencies, and other issues are identified and resolved more quickly when they do occur.

Digitalization also opens the possibilities of virtual design verification and validation early in the development lifecycle to drive optimizations and ensure the satisfaction of requirements. For example, the placement and integration of sensors around the vehicle body is critical to ensuring the proper functionality of these sensors. Certain locations on the exterior of a vehicle are more likely to be fouled with dirt or road spray, while others may be unsuitable for large sensors that generate a lot of heat. Digitalization can enable companies to investigate these parameters early in the vehicle design process, identifying potential issues well before any physical prototypes are constructed.

Key to this approach is a comprehensive digital twin that captures every aspect of the vehicle design and production (figure 3). Using such a digital twin, automotive companies can remove the barriers between engineering teams from across the electrical, electronic, software and mechanical domains. This not only helps companies overcome the complexity of AVs, but also fosters a new culture of collaboration and innovation in the company that will carry it through the challenges of tomorrow.

Figure 3: A comprehensive digital twin of the vehicle will be crucial to achieving the future of mobility technology. (credit: Siemens)

In sum, digitalization is a powerful enabler of technological innovation, collaboration, and informed decision making. By investing in digital transformation, companies of all sizes can tackle the challenges of developing the vehicles of the future by removing longstanding boundaries to collaboration and by fostering innovation through the maximization of available data. These capabilities will be crucial to all automakers as they pursue the future of mobility.

Latest from EV Design & Manufacturing

- Ford partners with Renault Group to expand European electric vehicle presence

- Analysis, trends, and forecasts for the future of additive manufacturing

- BlueForge Alliance Webinar Series Part III: Integrate Nationally, Catalyze Locally

- Wolfspeed’s silicon carbide components to power Toyota’s onboard EV charger systems

- Sunnen enhances e-commerce platform for precision honing equipment

- QuantumScape moves forward with automated battery cell pilot production line

- Dürr introduces next-generation low-pressure spray gun

- #56 Lunch + Learn Podcast with Techman Robot + AMET Inc.