TE Connectivity

Today’s eMobility (TeM): Is more attention being paid to making electric vehicle (EV) batteries hold a charge longer or installing more EV charging stations across the country?

Qingo Sun: Today’s EVs offer vastly greater driving distances than previous models, even those from five years ago, and they’re a lot of fun to drive. There is still some consumer hesitancy often associated with “range anxiety,” the distance a car can travel on a single charge. In addition to the distance concern, there’s a convenience phenomenon we like to call “charge anxiety,” the fear drivers experience because of the lack of compatible or “fast” public charging stations available to them. Drivers on long-distance road trips don’t want to wait in line for hours to recharge their cars, and once they’ve pulled up to the charging station, they’d prefer to have an experience more like a traditional gas station fill-up; five to 10 minutes and they’re on their way.

Automotive manufacturers have begun installing larger batteries in new EV models. While the larger batteries provide greater range, they also take more time to charge. To transfer energy in the quickest and most efficient way, EVs and fast public charging stations require larger cables and connectors. When the battery is bigger, the electrical infrastructure of the car needs to be more robust so energy transfer can happen more quickly. These new charging requirements require 10-20 times the power of the current generation of electric cars.

Today’s DC fast chargers provide between 50 and 200kW of power, which can add about 200 miles of driving range to a typical EV in about an hour. The industry is working on improvements that will deliver the same amount of range in 10 minutes or less.

This is where TE Connectivity comes in. TE’s e-mobility solutions are high-voltage, high-current connectors enabling the use of larger batteries. TE’s next-generation AMP+ charging inlets enable smarter, faster, safer charging and focus on transferring the amount (voltage) and rate of speed (current) of electricity from the electric grid into the vehicle.

More public charging stations are needed, and OEMs are placing a significant emphasis on building new EV architectures enabling fast, high-power, and megawatt power transfer, and TE is working to develop and implement those standards.

TeM: Have there been components or ideas from other industries you’ve been able to work into or reconfigured for EVs? Or have all your components had to all be brand new?

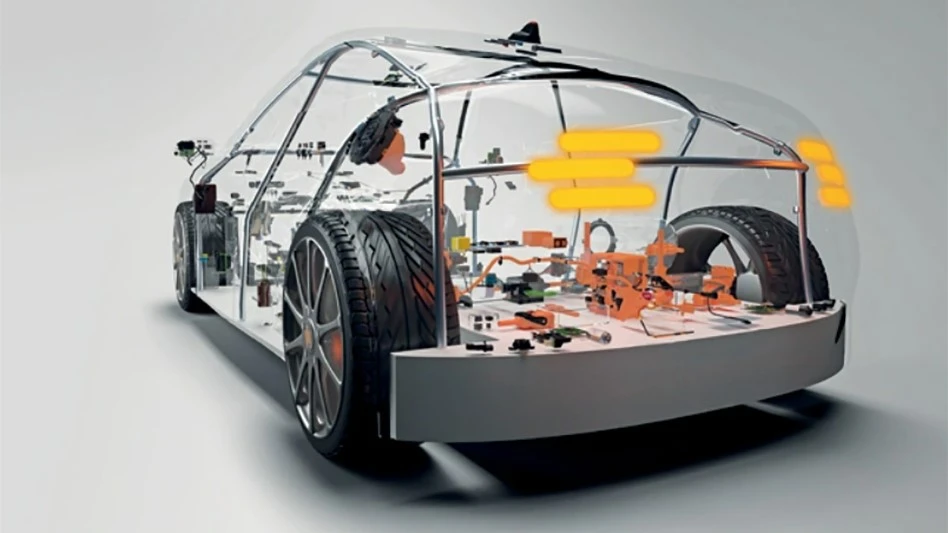

Sun: While the purpose of EVs and traditional cars is to get drivers from point A to point B, they differ greatly in their architectures. EVs require a new design thought process, with entirely new electrical systems and components that can support 400-, 800-, or 1000-volt systems in contrast with the traditional 12-volt systems of internal combustion engine (ICE) cars. Physical attributes like size, weight, bulk, and materials are critical considerations in the design of automotive applications, which is not always the case with other applications or industries. Automotive connectors also need to be assembly-line friendly since they are often connected by hand or via automation. Due to their unique requirements and specifications, EV components are purpose-built and can’t really be “borrowed” from other applications. TE can leverage scientific and engineering acumen in other industries when developing solutions for automotive applications. Understanding how to design and manufacture products that are durable, reliable, and resilient to harsh environmental conditions has given us a leg up in developing new connectivity solutions for EVs.

TeM: What advancements have been made to ensure EVs can work despite environmental factors (like blackouts/power outages, cold weather, storms, etc.)?

Sun: Unexpected interruptions in power delivery to a charging station would have a negative impact on an EV as it would prevent the vehicle from recharging. But the same could be said if a major storm were to interrupt fuel delivery or fueling station access for an Internal Combustion Engine (ICE) vehicle. Ironically, EVs provide a benefit during storms or power outages since many of them can serve as a back-up power source and transfer electricity back into a home, powering critical home components on a temporary basis until electricity can be restored.

TeM: What improvements need to be made to ensure EV safety?

Sun: The use of higher voltages in EVs creates new safety challenges compared with the lower voltages in ICE cars. TE is committed to an electrified future and is focused on protecting the car and its systems, which, in turn, contributes to greater passenger safety. TE addresses the protection of the sensitive components and instruments that make up an EV’s drivetrain, including the battery by producing safe, high-quality, reliable, and durable connectors and contactors. Contactors are electromechanical switching devices designed to disconnect critical components from the electrical system in the event of a short circuit or other electrical fault.

TeM: How far away are we from seeing widespread EV adoption throughout the US? What is TE Connectivity doing to make that possible?

Sun: While it’s unclear when exactly EVs will overtake ICE vehicles in terms of the total number of cars on the road, it seems inevitable that soon they will be the dominant platform. OEMs are literally introducing hundreds of new EV models. Many have committed to rewriting their business models and to investing billions of dollars into EV development and production. And some have even committed to phasing out their ICE vehicle production centers entirely.

The drivers accelerating this shift include government incentives, advancements in range and charging time, a superior driving experience that features faster acceleration and instant torque, a lower total cost of ownership, and perhaps most of all, EVs offer lower CO2 emissions and improved sustainability. Today, newly released EV models frequently sell out in minutes. And by 2030, EV production is predicted to increase seven-fold, with more than 40 million EV units expected to be produced annually around the world.

As the world shifts from ICE to hybrid and electric vehicles, TE Connectivity is an innovative force driving automotive electrification and new energy vehicles. In many instances our colleagues are embedded at OEM sites, co-engineering with our customers and helping them to enable their EV vision. TE creates and manufactures high-voltage e-mobility connectors, inlets, sensors, and contactors designed to deliver a safe, sustainable, productive, and connected future.