Monaghan Tooling

Monaghan Tooling Group (MTG) received a quote request from our distributor Butler Brothers in New England. Butler Brothers’ customer was in urgent need of a tool to produce a very fine micro-finish on a flat surface of a ventilator component. Production of these ventilator parts had to be ramped up to 2,500 per week by mid-April.

“As soon as we heard ventilator, we made this request our #1 priority. Even though this was a very urgent need for the manufacturing of life-saving and sustaining equipment, it was still critical to work within our process at Monaghan Tooling Group and Elliott Tool Technologies (ETT),” says Scott Monaghan, president, Monaghan Tooling Group.

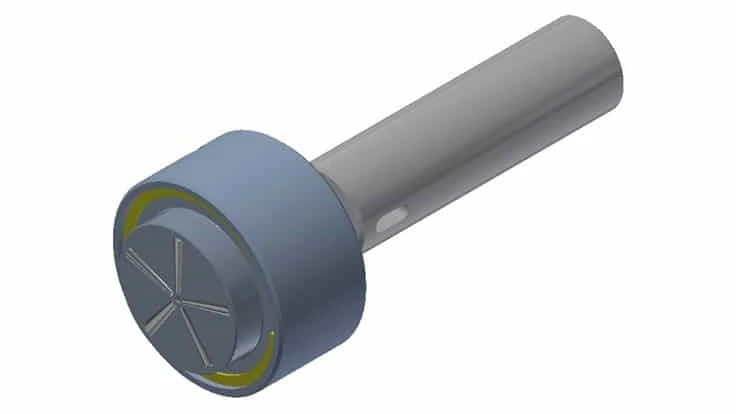

After reviewing the application, MTG determined that a custom designed flat-face multi-roller burnishing tool would do the job. Following some emails and phone conversations with Butler Brothers for clarification on what was needed, all questions were answered, and the decision was made by the customer to move forward and place the order.

“What happened next wouldn’t have been possible without the teamwork, communication and the shared urgency among everyone at MTG and ETT, knowing life-saving equipment was on the line,” says Andrea Rees, operations manager, Monaghan Tooling Group.

ETT’s modular flat-face tool design ensures quicker design, faster manufacturing, and higher quality. This particular tool is made up of 45 individual components: 11 of which are precision machined by ETT and 34 components are purchased items.

Click here for the timeline and rest of the details.