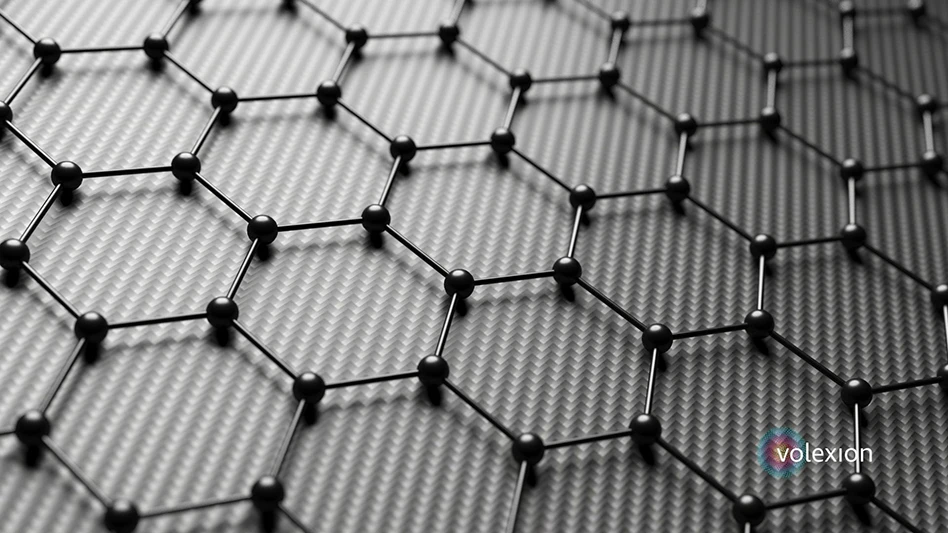

CREDIT: VOLEXION

Volexion, a battery materials company developing graphene‑coated cathode active materials (CAM) for lithium-ion batteries, has shipped its first product samples to tier‑one manufacturers worldwide. Initial recipients include leading automotive OEMs, top global cell producers, and U.S. specialty energy‑storage developers, with additional shipments already underway.

Why it matters:

Inside every battery, cathode active materials are in constant motion. Ions shuttle back and forth, particles expand and contract, and surfaces react with electrolytes. Over time, like moving parts in any machine, that natural interaction degrades performance.

Volexion’s graphene coating protects CAMs from this degradation, enabling batteries that last longer, charge faster, and deliver higher energy density, without retooling factories or disrupting supply chains. The technology works across established and emerging chemistries, including NMC, LFP, lithium-manganese-rich (LMR), LMFP, and LNMO, ultimately bringing graphene’s long-promised benefits to scale.

“Every lithium‑ion battery is fighting a slow battle against its own chemistry; cathode materials wear down as they work,” says Joe Adiletta, CEO of Volexion. “Our graphene coating shields those materials from that breakdown. It’s a drop‑in solution that extends life, boosts performance, and enables next‑generation chemistries without costly retooling.”

Close to a dozen early adopters across the supply chain are already evaluating early shipments. This list includes global materials producers, cell developers, and OEMs, among others. Volexion will partner with customers to apply the coatings, ultimately shipping larger quantities of graphene for scaled deployment over the next several years, according to customer timelines. Volexion uses commercially available off-the-shelf equipment, streamlining and de-risking scalability.

“This is a crucial milestone in our scale‑up journey,” says Damien Despinoy, president & COO. “Our customers’ increasing demand for scalable solutions for current and next-generation battery problems has driven deliveries across geographies, chemistries, and applications. This is just the beginning – and, with an easily scaled solution, we are ready to go.”

Volexion’s graphene encapsulation platform is chemistry‑agnostic and manufacturing‑compatible, positioning it as a critical enabler for the next era of battery innovation, from electric vehicles to portable electronics, grid storage to data centers, and drones to defense.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?