CREDIT: M. WAGNER, TU GRAZ

Electric vehicles (EVs) are very resource-efficient in operation, but the battery and associated components still generate a large ecological footprint during production. In the Bio!Lib project, a team led by Florian Feist from the Institute of Vehicle Safety at Graz University of Technology (TU Graz) has succeeded in manufacturing the protective housing of EV batteries from wood and thin sheet steel instead of aluminum. The environmental impact of this enclosure is significantly lower, and in some cases it even performs better in deformation and fire protection tests.

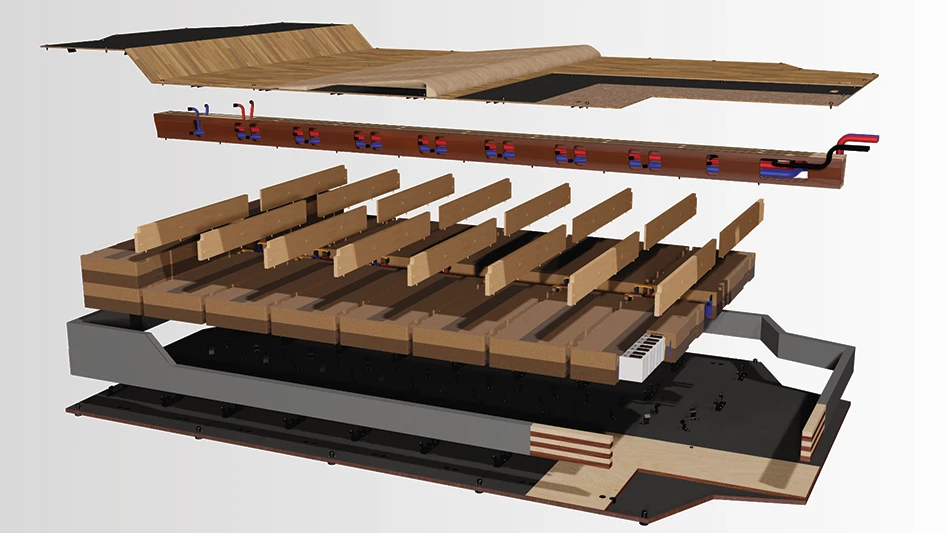

The battery housing is of crucial importance for the safe operation of EVs. In the event of a crash, it protects the battery elements from excessive deformation and thus from a battery fire. The housing usually consists of extruded aluminum profiles with a chambered structure. Such enclosures are safe, but very energy-intensive to manufacture.

Similar intrusion values to the Tesla Model S

“For this reason we have dispensed with aluminum in our Bio!Lib project,” says Feist. “Instead, we use a very thin steel skin whose chambers are filled with wood. The steel skin is welded directly in the presence of the wooden core.” Wood has the advantage of consisting of tiny cells that collapse under high pressure and can therefore absorb a lot of energy in the event of a crash. The underbody and lid are also made of this steel-wood composite, and the inside of the battery is reinforced with rib-like cross struts. “We were amazed ourselves at how well our housing performed in a simulated crash,” says Feist. In the critical pole crash test, in which vehicles or components collide with a round steel pillar at high speed, the intrusion values of the Bio!Lib housing are almost identical to those of the aluminum battery housing of the Tesla Model S.

Cork as fire protection

In addition to impact protection, fire and heat resistance are crucial functions of battery housings. The researchers also used a renewable raw material as a fire protection material: cork. “When cork is exposed to very high temperatures, it chars,” explains Feist. “Carbonization leads to a sharp drop in the already relatively low thermal conductivity, which protects the structures behind it.” This also applies to the interior of the vehicle. In a so-called pyrotechnic test, which simulates a battery fire, the battery cover withstood temperatures of more than 1300°C and bombardment with aluminum and copper particles. The cork-insulated Bio!Lib housing even outperformed the Tesla competition in this test: on the side facing away from the fire, the temperature was around 100°C lower.

To assess the sustainability of their metal-wood hybrid design, the researchers worked together with the Wegener Center for Climate and Global Change at the University of Graz to determine the environmental impact of all materials and components used – from the use of primary energy, water, and land to the pollution of soil and water with toxic substances. “In all areas, the Bio!Lib housing performs better than the market standard made of aluminum; only in the impact category ‘land use’ was it the other way around,” says Feist.

Follow-up project: Re-usability and recycling

In a follow-up project, the project team – consisting of renowned industry and research partners – now want to determine whether low-value wood (e.g. from thinning or secondary utilization) can also be used for the housing. The researchers also want to optimize the re-usability of the cork and the recyclability of the components.

Latest from EV Design & Manufacturing

- Powering homes with EV batteries could cut emissions, save thousands of dollars

- Meviy introduces stainless steel passivation option for CNC, sheet metal parts

- December Lunch + Learn webinar with Fagor Automation

- December Lunch + Learn webinar with LANG Technik + Metalcraft Automation Group

- EVIO makes public debut with hybrid-electric aircraft

- Redesigned pilot step drill triples performance

- Green Energy Origin expands battery electrolyte manufacturing in North America, Europe

- What’s next for the design and manufacturing industry in 2026?