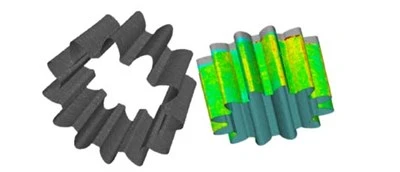

A new measurement module enables the measurement of all teeth of a micro gear in a single measurement. Based on the cooperation with Frenco, international specialist for gearing technology, it is now possible to measure deviations from the involute of a tooth flank. Measurable parameters include form and slope deviations of both profile and helix, single and cumulative pitch deviations, as well as run-out error. Paired with a precision rotation unit, you can achieve full geometry measurement of micro gears, enabling the measurement of geometries such as tooth thickness, space width, and pitch diameter.

In contrast to conventional measurement techniques, the optical and area-based technology of Focus-Variation allows for the measurement of all tooth flanks of a micro gear. Based on the largest deviation compared to the CAD data set the relevant positions for the extraction of the profile and helix are easily defined, revealing parameters about the maximum deviations of the manufactured gear.