CREDIT: ARKEMA

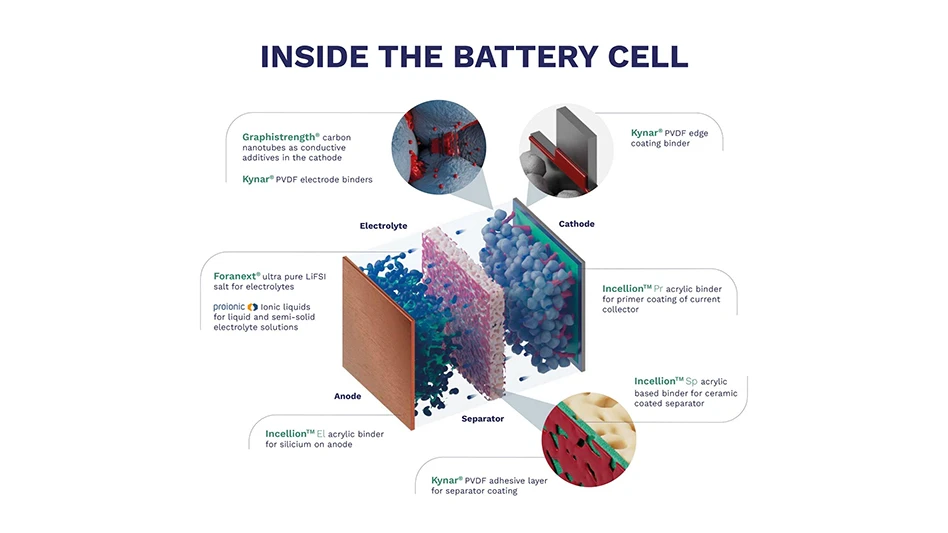

Arkema, developer of specialty materials, is set to showcase its portfolio of solutions and innovations for electric vehicle (EV) and energy storage system (ESS) battery systems at the Battery Show Europe 2025 in Stuttgart, Germany, June 3 to 5. For decades, the company has been supporting the battery industry through every stage of its evolution, by providing innovations for inside and outside the cell.

Arkema will display its offering of high-performance and sustainable materials for current and next generation battery cells and packs at Hall 8 Booth F10.

On top of its existing wide range of solutions for the current generation of cells, module, and packs, Arkema will showcase its innovations related to safer, higher performance, and more sustainable batteries:

Innovative materials for semi-solid batteries

This new offering is specifically designed to support the development of gel electrolyte batteries.

It offers the combined benefits of leading battery technologies: scalability of liquid electrolytes and enhanced performance and safety of solid-state technologies.

Electrode binder solutions for dry coating process

Arkema will highlight its Kynar PVDF electrode binder, enabling battery manufacturers to adopt more efficient and sustainable dry electrode coating processes.

The Group is investing in lab-scale dry coating facility in France, with dedicated R&D resources to develop new materials and to support the next generation of manufacturing processes.

Disassembly in mobility

This year, Bostik is unveiling Prep DB, a primer designed to tackle the challenges of vehicle repair and end-of-life recycling.

Developed as part of an Open Innovation strategy, this thermal activation technology enables the bond to break, allowing components to be disassembled without damaging surrounding materials.