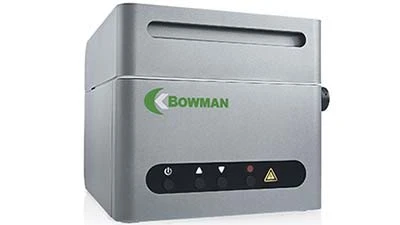

Schaumburg, Illinois – Bowman’s G Series XRF benchtop plating measurement system is ideally suited for connectors and other precious metal analysis. Because it quantifies zinc, zinc-nickel, and other anti-corrosion coatings, it is also ideal for components such as fasteners.

The two most distinctive features of the G Series are bottom-up measurement using a motorized Z-axis with laser-based auto-focus, and precision video imaging. An available manual XY stage with 1.5” X 1.5” travel facilitates easy positioning of small and large parts.

The standard G Series configuration includes a single fixed collimator, solid-state PIN detector, and long-life micro-focus x-ray tube. The components can be upgraded to include multiple collimators, a variable focal camera, or an SDD detector.

G Series instruments simultaneously measure up to 5 coating layers, 10 elements in each layer, a total of 25 elements. Element range is Al (13) through U (92.)

To quantify coating thickness from the detected photons, G Series systems run advanced Xralizer software. Xralizer combines intuitive controls with time-saving shortcuts, extensive search capability, and one-click reporting. The software also allows easy creation of new applications by the user. Equally important: G Series XRFs are full-access instruments from the day of install: there are no dongles or lock-outs to complicate, delay, or add cost.

Bowman’s G Series desktop XRF was developed for quality labs and production environments. It is highly advantageous for users with limited benchtop space - or budget limitations. G Series XRFs are ideal for both coating thickness and solution analysis.