Cabin interiors are changing, in the premium market, most passenger cars, both light and heavy commercial vehicles. Passengers are demanding comfort and cleaner lines free of cumbersome buttons and switches.

This is driven by people spending more time in their vehicles due to heavier traffic and the demand to complement technological advances such as high-end entertainment systems, mobile internet connections, and the use of superior quality materials. The interior environment must live up to expectations in comfort, functionality, and aesthetics, and will be a core element of focus in future vehicle development.

Through advances in material development, designed to close the technology gap between internal combustion engine (ICE) vehicles and new mobility applications, several areas within the cabin interior have been identified to benefit from EAP technology.

How does EAP stacked actuator technology work?

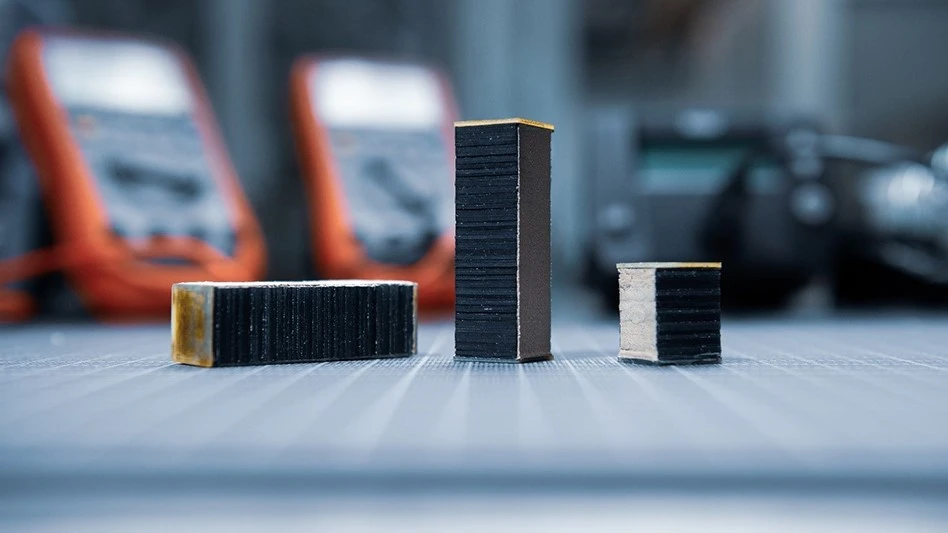

Electroactive polymer components are made of very specific materials change their shape or their behavior once a voltage is applied. Stacked actuators consist of small capacitor cells, and each single capacitor cell consists of an electrode and a dielectric barrier in between. This dielectric is made of a soft and flexible rubber material with high insulation properties. If the electrodes are charged with a voltage, the electro plates start to move towards each other, creating an axial motion. Electrical energy is transformed into mechanical motion.

Since a single cell of a capacitor is only 15-20microns in thickness, the axial movement is relatively small. To create useable motion, it’s necessary to stack the cells in a polymer transducer to increase the axial movement and address functionalities. The transducers can be used for actuation such as controlling the flow of air into a valve among other functions.

Because of capacitor working principle, stacked polymer transducers can keep position without permanent energy feeding as voltage is stored on electrodes. Just for long term positioning, a certain minimal leakage of voltage needs to be compensated. By charging the voltage (charging and discharging) the stack follows in proportional and stepless way the amount and profile of voltage. This means movements can be realized without mechanical components. The movement follows the amount of applied voltage strictly. In actuation and sensing they offer high versatility of operation and are highly controllable.

Where can stacked actuators be used effectively in car interiors?

Pneumatic comfort seats

Massage seats have required multiple mechanical components to operate within a vehicle. In one high end model there are up to 16 e-motors required to drive the in-seat massage function. This adds considerable weight to the seat itself, and bulk, leading to a less comfortable ride for the passenger.

With the EAP alternative, cushions located strategically within the seat are connected via tubes with an EAP controlled valve system, featuring valve boxes and a pump which creates a permanent overpressure of air. The system is filled with air at a carefully calculated pressure and the EAP controlled valve blocks make sure each cushion is inflated or deflated at a certain frequency to create a massage effect.

The EAP system is non-mechanical, so it is lightweight when compared to a conventional solenoid system, and only requires energy for initiating traction. To elongate the material the energy is removed, and as a result can be recovered, making it a very efficient system.

As these comfort seat systems will be largely deployed in battery electric (BEV) vehicles in the future, autonomy of the battery is a critical point, and it is desirable to reduce all related energy inefficiencies in order to protect effective range. In a mechanical system or even a pneumatic system driven by electro-mechanical or solenoid valves, this is more difficult to achieve. However, by using EAP stacks integrated into the vehicle control system, it is not only possible to recuperate energy as aforementioned, but also to reduce the weight of the seat itself. Overall, the complexity of the system is reduced, and the range of the vehicle is less affected in comparison with conventional technologies.

Air vents

The actuation of air vents is also possible using EAP technology and is another example of where the noise free function is highly desirable within the cabin interior. In general, air vents are in the middle of the dashboard and to the left and right, which will be replaced in the future by what will be called a broadband or cross-dashboard air vent.

Clean vehicle interiors will have no switches and buttons and will largely feature screens and flat surfaces. Therefore, these new look air vents will fit in with the aesthetics through subtle integration into the overall design. The integrated EAP stacks over a mechanism can open and close the blades in the air vents, and dedicated flaps will move using a leverage system to control the position of the vents with close to zero disturbance to the occupants of the vehicle when in operation.

Morphing surfaces, haptic feedback

Switches and buttons will eventually be phased out in the cabin interior, and with the cleaner lines in terms of design it is possible to integrate what are known as morphing surfaces. Here, the EAP stacked actuator is positioned beneath the dashboard surface. Sensors are used to activate hidden functions when a hand approaches the surface, and a button will appear driven by an EAP stack.

The same EAP stack can be used to deliver haptic feedback to the user via a pulse or vibration, confirming a command has been received and actioned once the button is pressed. Currently, e-motors and piezoelectric elements are used to deliver a similar function, but by using EAP actuation both the morphing surface and the haptic feedback can be achieved using a single stack. Based on vehicle segment, it is estimated that 15+ units per vehicle will be commonplace by as early as 2028.

The potential for use cases within the cabin interior does not stop here. Essentially, wherever conventional actuation is currently used there is the opportunity to replace it with EAP alternatives, whether it be connected to the operation of a valve or pump, or even to provide haptic capabilities linked to areas such as the steering wheel or navigation system. The benefits as outlined remain the same and are in perfect alignment with the transition to new mobility applications such as battery electric and hybrid vehicles.

As technology continues to advance, and the level of autonomy in vehicles increases, both comfort and aesthetically pleasing functionality will continue to rise up the list of priorities for drivers and passengers globally. Advances in the areas outlined in this article will likely be a standard in the not-too-distant future, and through advances in material development such as the EAP stacked actuator there will be no reason for compromise. Space can be saved, autonomy protected, and comfort and style guaranteed.