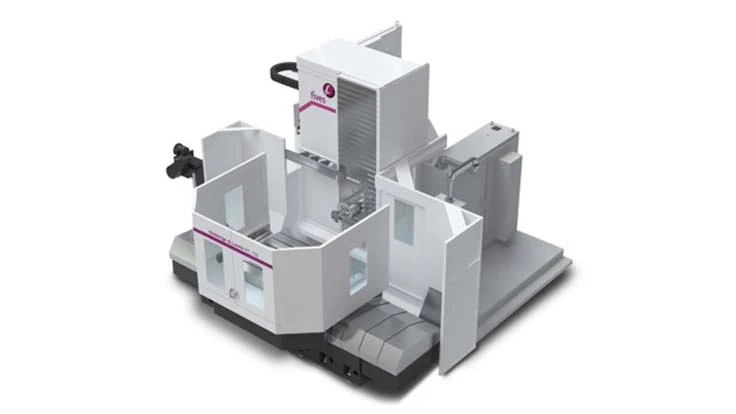

Fond du Lac, Wisconsin – A new line of U.S.-built T-bed boring mills with high accuracy and cutting capacity, are designed and priced for job-shops.

T-bed or travelling column boring mills move the column in the Z-direction and the tables in X. Engineered for flat-floor installation, small footprint and low ceiling clearance, the first models of the machine are configured with a 10,000kg capacity (22,000 lb) 1,250mm x 1,400mm (49.2” x 55.1”) contouring rotary table. Optional 1,400mm x 1,800mm (55.1” x 70.9”) tables are available.

The new machine will be exhibited at IMTS in booth S-8109.

The mills are heavyweights, designed with cast-iron structures, a cross-braced column for torsional stiffness, linear scales, a precision hydrostatic contouring table and 25kN thrust capacity.

The machines are sized to fit the smaller physical plant of most job shops and tool rooms. Low height and flat-floor installation facilitate machine relocation if necessary. An integral table-mounted pan helps contain chips and coolant.

High-end features include an electronically counterbalanced Y-axis headstock for superior contouring performance. The side-hung headstock improves visibility and access for the operator. The spindle snout reaches over the table for rigid cutting without extension and with spindle travel extends well beyond center. In addition, the spindle can reach below table top to probe for location on the table or a particular feature. Permanently greased spindle bearings reduce maintenance. The zero-backlash rotary table is powered by two independent motors and pinion drives that are tensioned against each other to compensate for any lost motion.

The RT 130 and RT 155 boring mills feature 130mm or 155mm (5.1” or 6.1”) diameter gear-driven spindles available with up to 45kW (60hp) and 3,380Nm (2,493 lb-ft) torque. All spindles are size 50 tool taper, and equipped with Giddings & Lewis' spindle thermal growth compensation.

Heavy-duty linear ways on these machines utilize roller bearing carriages that ride on hardened and ground guideways. This rigid, low-friction system supports high loads and fast traverse speeds. By eliminating the stick-slip and thermal growth common to box ways, linear ways facilitate better true positioning and contouring accuracy. They also require less lubrication, thus reducing coolant contamination. Standard X-Y-Z axis travels are 2,000mm, 1,500mm, and 1,600mm (78.7”, 59.1”, 63”) with W-axis spindle travel of 750mm (29.5”).

All CNC's for the new machines are equipped with Fives Machining Systems’ Diagnostic Communications System (DCS). The DCS allows customers to connect with technicians on a secure system to review active alarms and operator messages, operator and alarm histories, control parameter settings, PLC programs, and the state of devices such as solenoids, switches and encoders. According to Fives, 30% to 40% of stoppages can be overcome immediately this way without waiting for a service call.

Source: Fives Metal Cutting I Composites