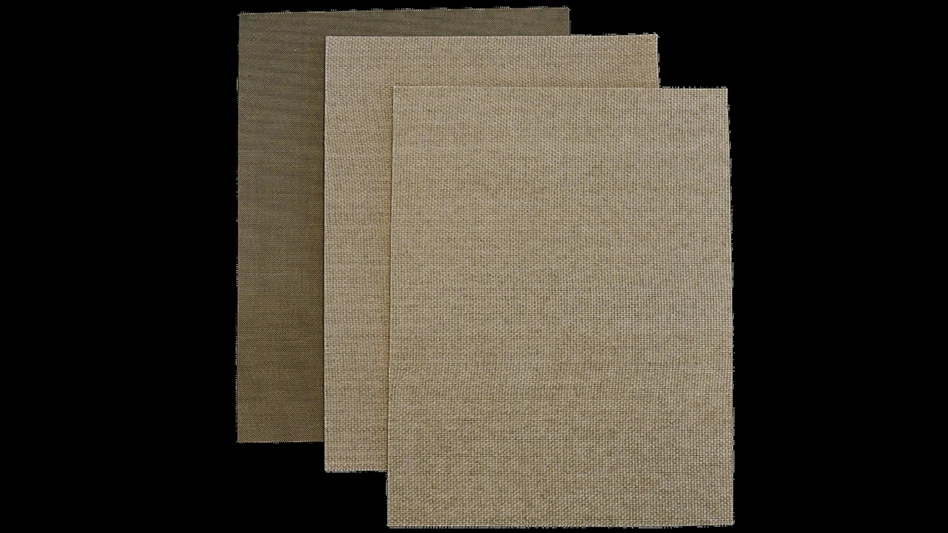

CREDIT: BLUESHIFT

Blueshift, a developer of advanced thermal protection systems (TPS), has launched its AeroZero Flame & Thermal Barriers (FTBs), a portfolio of ultra-thin, lightweight, and flexible flame and thermal material solutions that can withstand exposure up to 1200°C for 30 minutes.

With the continuing global adoption of electric vehicles (EVs) and aerospace electrification, Blueshift’s latest addition to its AeroZero family is ideal for a wide range of applications and industries that can experience extreme temperature fluctuations; from EVs and aerospace markets to marine and rail.

For example, within the field of EVs, FTBs are primarily used as a safety barrier material aimed at preventing the transfer of extreme heat or fire that can result in mechanical damage of battery cells and exposure to high temperatures or discharge events. Blueshift’s AeroZero FTBs can withstand exposure up to 1200°C for 30 minutes whilst maintaining a cold-side temperature below 300°C. This means they can either be used as safety features in preventing uncontrolled fire, for example due to an aircraft engine fire, or protecting surfaces from direct exposure to flame such as during a rocket take-off or helping to mitigate the risk of a battery thermal runaway event.

Outperforming traditional mica, silica, or polyurethane foams, AeroZero FTBs are up to 80% lighter, with a thickness range of 0.32mm to 1.77mm – significantly thinner than conventional barriers (3mm to 10mm). Alongside this, their ease of use and flexibility is a key factor influencing engineers’ decisions to integrate the new materials into their designs. With their peel-and-stick pressure sensitive adhesives (PSA)-backing that simplifies installation on irregular surfaces, labor time and cost can be drastically lowered.

Tim Burbey, president at Blueshift, says AeroZero FTBs aim to set a new benchmark within the industry: “Traditional thermal insulators have often been based on polymeric foams or ceramic blankets that can suffer from drawbacks due to their added weight, thickness, toxic off-gassing, lack of flexibility, and processing issues. As EV adoption ramps us alongside aerospace electrification, our AeroZero FTBs will unlock new performance capabilities by enabling the next generation of aircraft and vehicles to be safer, lighter and more efficient.

“Available across multiple ranges, we look to incorporate as many vehicles and industries as possible, so everyone can overcome their unique thermal challenges that other FTBs in the market simply cannot.”

The AeroZero FTBs family includes, AZ-FTB 100 for up to 500°C applications, AZ-FTB 101 for up to 800°C, and AZ-FTB 300 for maximum protection up to 1200°C. These advanced FTBs are well-suited for protection in EV battery modules and aerospace components that see indirect and direct exposure to flames.