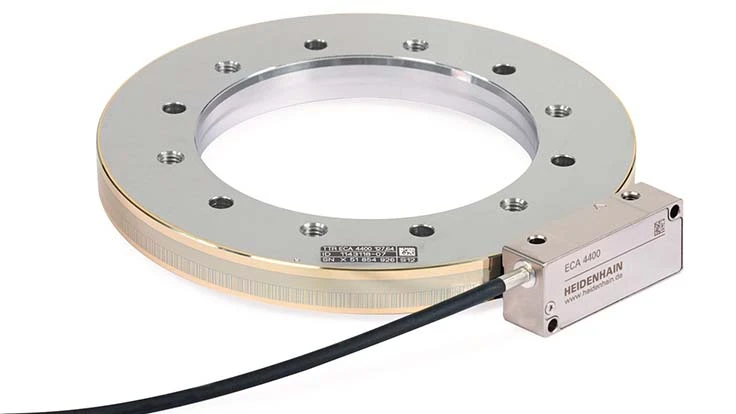

Schaumburg, Illinois – The ECA 4000 adds absolute technology for angular motion feedback to the ERA 4000 incremental ring encoder, an encoder used in machine tool rotary tables, semiconductor wafer motion stages, and robotics.

The mechanically-compatible ECA 4000 series comes in a wide range of outer diameters ranging from 104mm to 560mm so that machine designers can pass through cabling and other items through the center of the ring to streamline their design.

Each ring has a three-point centering method, which allows the installer to locate the center of the drum to the center of the machine bearing within a couple of minutes. Then a shim or separately ordered plastic mounting tool is used between the reader head and drum to make the appropriate scanning gap.

Each ring size has a unique line count on the outer diameter and an associated accuracy. For the largest ring diameter, an accuracy of ±1.50 arc seconds is specified for the graduation, and each ring is capable of resolutions to sub 0.01 arc seconds, all with high RPM potential. The two-track graduation design is also highly resistant to contamination, dust, fingerprints, and scratches.

In addition to the ENDAT 2.2 high speed pure serial interface, the scanning units on the ECA 4000 series also come in Fanuc 05 and Mitsubishi 03-4 serial interfaces.

Source: Heidenhain Corp.