Marposs, a global leader in measurement, inspection, and test technologies, has announced its systems for Testing Prismatic Battery Cells including checking of dimensional characteristics, safety conditions, and electrical functional parameters. This machine can be easily reconfigured to adapt to different cell sizes and is suitable for end of line control or verification and grading at the beginning of a module assembly line. With the growing market for electric vehicles, manufacturers are under increasingly aggressive production schedules while ensuring quality and controlling costs. Marposs can help automakers manage their quality control, improving both process and product quality and decreasing waste.

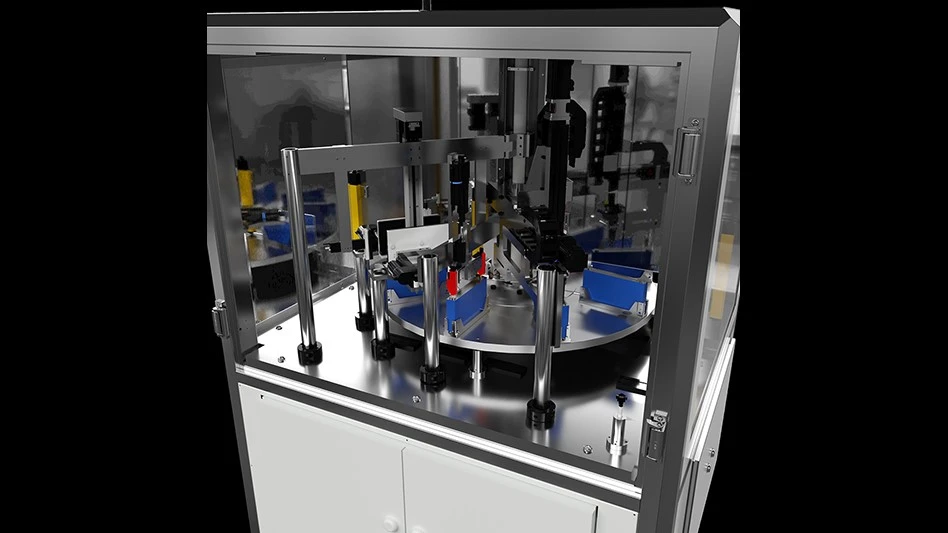

Originally designed as turntable system, the testing system can be loaded manually by an operator or through automation. Capable of handling up to 18 nesting stations, the arrangement is determined by the specific battery cell model and size. Marposs can also design the solution as an in-line station or end-of-line with conveyors.

Dimensional Check: The system begins by checking the cell’s main dimensional parameters using contact or chromatic confocal technology. A dedicated gripper, actuated by a servocontrolled two-axis manipulator, acquires the thickness of the cell in different contact points along the body of the cell itself. Number and position of the measuring points can be easily programmed according to customer’s requirements.

Electrical Check: The main station is dedicated to the electrical testing, where pogo-pin device closes the circuit between anode and cathode with a controlled force. The main functional electrical parameters, such as Open Circuit Voltage (OCV) and Alternating Current Internal Resistance (ACIR), are then measured. Other measurements such as Direct Current Internal Resistance (DCIR) or complete Electrochemical Impedance Spectroscopy (EIS) can be made at the customer's request.

Then, the integrity of the electrical insulation is checked (Hi-Pot test) by contacting all external surfaces with a conductive foam. At this stage, the system can also be designed to perform a Y-Capacitance test.

Leak Test: Finally, the sealing is verified in a leak testing station. Since the cell is already closed, direct tracing of electrolyte vapors in a vacuum chamber is used, a technology that Marposs has expressly developed and fine-tuned to ensure maximum testing speed in automatic applications designed to control mass production lines.

All the collected data are then stored in association with the serial number of the cell, read on the data matrix code.