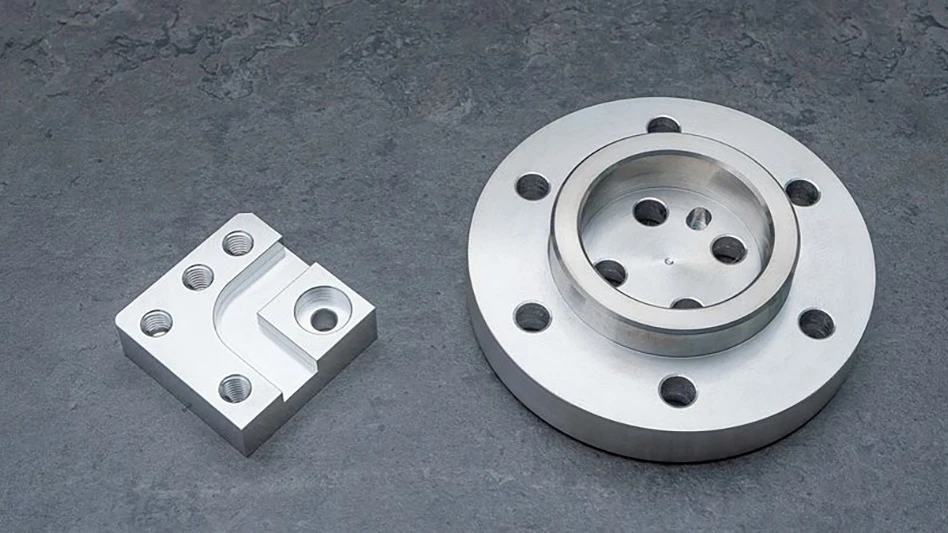

CREDIT: MEVIY

meviy, the on-demand custom parts manufacturing service developed by MISUMI Group, Inc., announces the launch of its new Stainless Steel Passivation offering for CNC milled, CNC turning, and sheet metal components. This enhancement strengthens meviy’s lineup of finishing options and gives engineers, designers, and procurement teams more control when producing stainless steel parts for high-performance applications. The introduction of Stainless Steel Passivation aligns with the platform’s commitment to provide reliable solutions for corrosion resistance, cleanliness, and durability.

By adding this capability, customers can improve surface protection and reduce the risk of contamination without involving additional vendors. Consolidating production and finishing through one digital manufacturing platform helps users source more efficiently while selecting the most appropriate materials and finishes. Material certifications remain available upon request through the manual quote process. In addition to this new treatment, meviy continues to support a wide range of manufacturing technologies, including CNC machining, CNC turning, and sheet metal fabrication, helping teams streamline procurement and accelerate development cycles.

Passivation is a widely used chemical process that removes surface contaminants and creates a protective oxide layer on stainless steel. Nitric acid is the standard solution for this treatment, valued for its ability to deliver consistent, high-quality corrosion resistance across a broad range of stainless steel grades. By using nitric acid passivation, manufacturers achieve cleaner surfaces, reduced susceptibility to rust, and improved long-term durability. This treatment is commonly required for components used in medical, laboratory, commercial, and industrial environments where surface integrity and cleanliness are critical.

This new treatment is offered through the Manual Quote workflow and supports 303, 304, and 316 stainless steel across sheet metal, CNC milling, and turning services. This allows users to apply enhanced corrosion resistance to a broad variety of part types produced through CNC machining, CNC turning, and sheet metal fabrication, ensuring consistency and performance across projects.