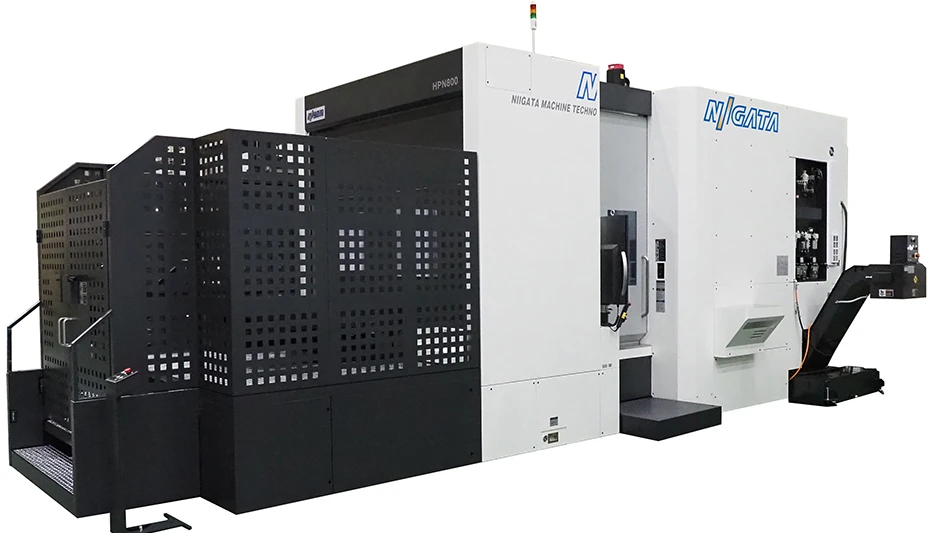

CREDIT: NIIGATA

The Niigata HPN800 horizontal machining center offers speed and flexibility, making it ideal for production of larger parts across a wide range of materials and industries. It’s equipped with a 75 horsepower, high-torque spindle and offers various tool and pallet system options.

The machine is ruggedly built for optimizing operations and increasing throughput and efficiency to reduce costs, even in the most demanding production environments.

The HPN800 features an ultra-rigid T-shaped base with honeycomb structure and 3-point leveling to the rock-solid spindle, advanced lubrication and cooling systems, accessible service points, and built-in diagnostics. It also incorporates Niigata’s hybrid guideway system with rapids of 2400ipm for high productivity.

The machine also includes Niigata’s cam driven ATC system with 2.5 second tool to tool time and carousel type multi-pallet system and flexible manufacturing system (FMS) with Niigata’s Intelligent Cell Controller (ICC).

HPN800 key features:

- A horizontal machine for combined substantial rough machining with precision finish processes.

- Higher productivity, heavier duty, greater workpiece envelope, and variety of high performance spindles.

- One-piece ultra-rigid T-shape machine base with honeycomb structure and three-point leveling.

- Niigata’s hybrid style guideway system.

- Higher productivity with rapids of 2,362ipm and cam driven ATC system with tool to tool time of 2.5 seconds.