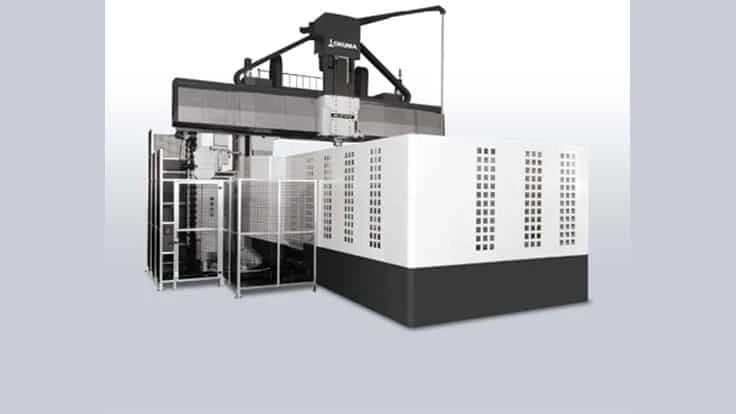

Okuma America Corp. debuted a double-column machining center (DCMC). This new machine – the MCR-BV - is the seventh machine offered in the company’s double-column machine line-up.

Designed as a machine for 5-face machining applications, the MCR-BV is also capable of 5-axis contouring as well as 5-sided heavy milling applications. These applications are possible with a powerful integral motor and spindle, an expanded work envelope, and a very rigid table which is 30% thicker than previous models. Attachment heads are compatible with the machine creating for a wide range of unique part shapes and performing many multitasking machining functions.

Additional machine features include a fast automatic tool changer (ATC) and a smaller, faster auto attachment changer (AAC), both of which allow this DCMC to greatly increase productivity while performing heavy cutting or high-accuracy finishing.

Specs of the MCR-BV Double-Column Machining Center:

• Table Size mm (in) 2,000 x 4,000 (78.74 x 157.48) to 3,000 x 12,000 (118.11 x 472.44)

• Spindle Speed min?¹ 6,000 [10,000 option also available]

• Spindle Motor Power kW (hp) 43 (57)

• Rapid Traverse m/min (fpm) X: 30 (98.43), Y: 32 (104.99), Z: 15 (49.22)

• Magazine Capacity 50, 80, 100, 120 or 180 Tools