CREDIT: STAR SU

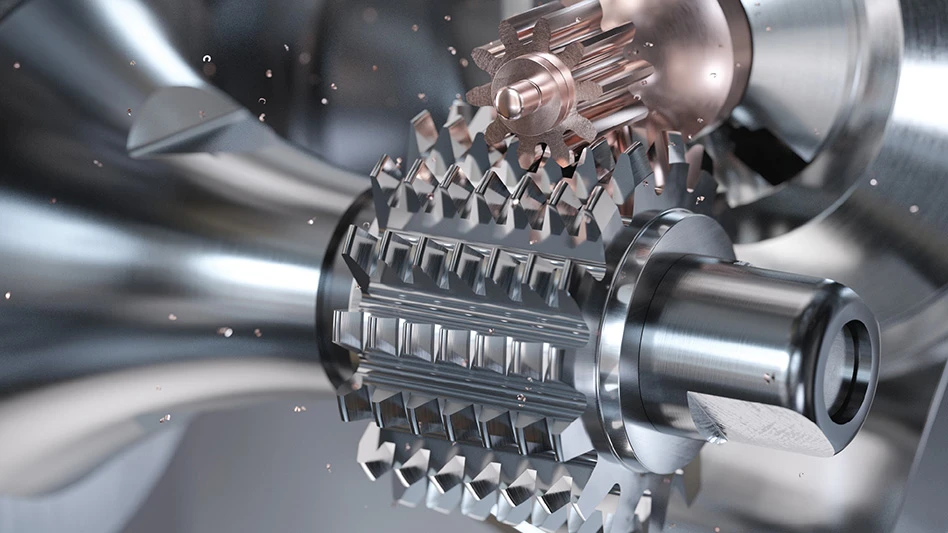

Given recent developments in machine tools, modern gear production is no longer tied to dedicated hobbing, shaping, or skiving machines. Advances in 5-axis CNC machining centers and turn-mill machines now enable manufacturers to cut gears with precision and efficiency, using specialized tools designed for multipurpose platforms. In booth #559 at the Motion + Power Technology Expo 2025, Star SU will illustrate how the combination of these tools and universal CNC machines can unlock gear manufacturing flexibility.

The company’s range of tools for universal machining centers include form cutters, hobs, power skiving cutters, and shaper cutters, as well as customized carbide round tools – empowering manufacturers with the speed, accuracy, and flexibility needed to stay competitive in modern gear production. Benefits of these new machines and tools include:

- Flexibility: Easily switch between gear types and sizes without retooling entire lines.

- Process integration: Combine turning, drilling, milling, tapping, and finishing in one setup, reducing cycle time.

- High precision: Achieve micro-level accuracy, ensuring superior gear profiles and surface finish without repositioning errors.

- Cost efficiency: Eliminate the need for dedicated gear machines in low-volume or prototype production.

Chamfer hob

Star SU will introduce its newest chamfer hob for gear manufacturing. Engineered for both precision and efficiency, this new gear making tool delivers burr-free chamfers in one seamless process.

Chamfering methodology (shaping the edge where the tooth meets the gear face) is critical to gear performance, durability, and safety. Without proper chamfering, gears risk breakage under heavy loads and high speed, burrs can damage gears and bearings, and sharp edges pose risks to operators. Smooth, accurate chamfers ensure better gear meshing, reduced vibration, and longer tool life.

The new Star SU chamfer hob, which performs like a hob tool, cuts material cleanly in a single process, eliminating the need for extra finishing and offering many benefits including:

- Burr-free, high-precision chamfers

- Resharpenable for long tool life and low cost

- Versatility for standard or complex gear profiles and interference limitations

- Optimized for large-scale production

Backed by Star SU’s expertise and advanced 3D kinematic simulation, the chamfer hob is tailored to individual gear geometry for maximum precision and reliability. Additionally, it can solve chamfering challenges such as shaft gear with shoulder interference, ring gear with fixture interference, and Inclined Lateral Surface Gear, etc.

This new chamfer hob has been proven by leading machine builders, setting new benchmarks in helping manufacturers achieve stronger, quieter, and more reliable gears while reducing cost.

Louis Bélet micro-capable hob cutter

Star SU will debut the new 8100 series hob cutter from Louis Bélet. With just a single toolholder, this new cutter places fine-pitch capability directly into Swiss-type machines. Shops can now produce flawless, high-quality gears without the cost, complexity, and footprint of a dedicated hobbing machine. This enables shops to upgrade and transform their Swiss machines into highly capable gear cutting equipment.

The 8100 series hobs are characterized by the high precision of the profile as well as the geometry of the whole tool. The series is suited for involute gears ISO53 /DIN867 – DIN quality AAAA in microtechnology applications within the watchmaking, automotive, or medical markets. Standard modules range from 0.050 to 1.000 every 0.05 with other modules available upon request. It is available in coated or uncoated versions and with or without a shank.

Alcrona EVO coating

Star SU will showcase the availability of Alcrona EVO advanced coating technology for application across the entire Star SU gear cutting tool portfolio. Alcrona (AlCrN) EVO is a titanium-free coating with excellent wear resistance that is optimal for high volume production applications.

When applied to cemented carbide tools, AlCrN-based hard coatings have proven to deliver high process reliability and exceptional service life, helping to increase uptime and decrease total cost per part. For example, a high-volume gear manufacturer using the latest Alcrona EVO-coated tools has achieved a 37% increase in total number of pieces per use, resulting in a 20% decrease in tool cost per piece.

Joining the other coatings available on Star SU gear tools, Alcrona EVO has a maximum service temperature of 1100°C and tools with this coating can be reconditioned and recoated without degrading performance. The Star SU team will work with customers to determine the best coating for any application.