Strausak AG, Lohn-Ammannsegg, Switzerland decided to open a subsidiary in Mundelein, IL and incorporate in the state of Illinois as of July 1st, 2014. Hank Ecker, previously regional sales manager of Rollomatic Inc, has assumed the responsibility of Strausak Inc. as its president.

Rollomatic Holding, LeLanderon, Switzerland acquired Strausak in 2011. With the R&D, purchasing power and other

recourses of Rollomatic, the new and restructured Strausak organization continued the design of innovative precision CNC grinding machines. Strausak has been well known worldwide for providing CNC tool grinding solutions with unsurpassed precision and flexibility, such as the legendary 5-axis Fleximat. As one of the first users of the renowned NUM control and Numroto tool grinding software, Strausak knew the necessity of super-flexibility and productivity for grinding specialty cutting tools and for resharpening. The return to the USA marks an important milestone in their long history. Strausak is one of the oldest names in the CNC tool grinding field and already delivered NC-controlled tool grinders in the early 1980’s. Strausak completed the first design and delivery of a production machine for the automated manufacturing of watch parts in 1927.

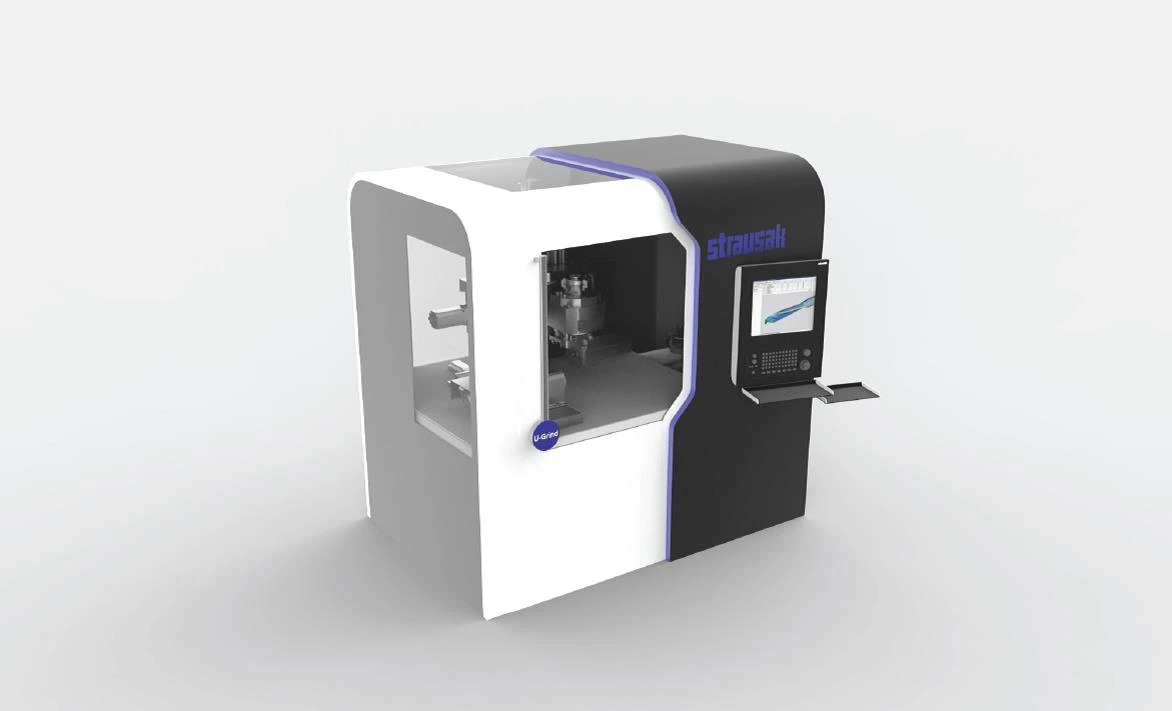

Strausak U-Grind 5-axis Universal CNC tool & cutter grinder. Standard with automatic wheel changer, and optional with automatic pick-and-place loader. Extremely tight thermal stability to facilitate consistent and highly accurate small batch production and regrinding. Direct-drive grinding spindle 12 kW (18 HP). Automatic quick-change system for collet change and for changing basic tool holder ISO-50 taper. NUM control Fleximum and latest generation of the well-proven Numroto tool grinding software. Software for all types of cutting tools, including complex step/ form tools. Hobs, burs, shape cutters, T-slot and more. Authorized drill point grinding for well-known manufacturers, including K-land grinding. 3D tool and machine simulation and collision check. Digitizing of existing cutting edges for regrinding or grinding pre-fluted tools.