CREDIT: VISUAL COMPONENTS

On the first day of FABTECH 2025, Visual Components, developer of simulation and robot offline programming (OLP), debuted its highly anticipated Visual Components 5.0 software platform. The more powerful platform provides all-in-one manufacturing simulation and advanced OLP. The company’s flexible and customizable software eliminates guesswork for manufacturers implementing automated processes and systems.

For all-in-one simulation, Visual Components 5.0 refines digital manufacturing workflows through a unified platform for layout design, process simulation, and virtual commissioning. Its debut brings significant advancements in performance, connectivity, and customization for better versatility among manufacturers and system integrators.

“Ultimately, version 5.0 runs faster and puts more control in the hands of users,” says Graham Wloch, director of Business Development at Visual Components. “For engineers, production floor managers, CEOs, and everyone working through the steps of digital production planning, it increases clarity of the process and confidence in the results.”

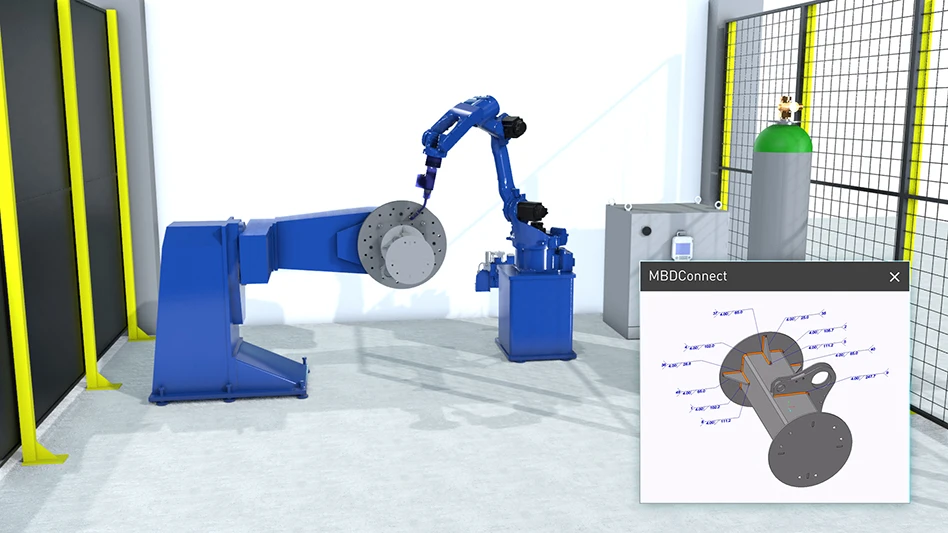

The upgraded end-to-end simulation capabilities are complemented by the most advanced level of OLP automation to date. Now, manufacturers can fully leverage model-based engineering from the earliest stages of production planning to final execution. Visual Components 5.0 supports model-based definition and product manufacturing information in one environment with compatibility across multiple brands. In turn, vital data is extracted directly from current CAD files for the robotic program.

“Brand-specific requirements create barriers for manufacturers or, at best, force them to use unreliable manual processes for data transfer,” Wloch says. “We eliminate the barrier to ensure tolerances, dimensions, surface finishes and additional specifications move seamlessly to the automated system.”

The new platform also supports modern scripting with a variety of programs, which gives its users the ability to tailor simulations, automate repetitive tasks, and work with widely used libraries. For manufacturers with a welding applications focus, Visual Components 5.0 integrates automated welding parameter applications, collision-aware path solving, and compatibility with other welding systems.

Connectivity is also widely expanded compared to its original version to support real-time simulation data across multiple hardware and robot systems. In addition, smarter collision geometry ensures smooth and accurate simulation even in complex environments.

To learn more about Visual Components 5.0, attendees at FABTECH can visit the Visual Components booth #B12045 in Hall B of the North Building of McCormick Place, Chicago, Illinois through September 11, 2025.