CREDIT: RAYTRON

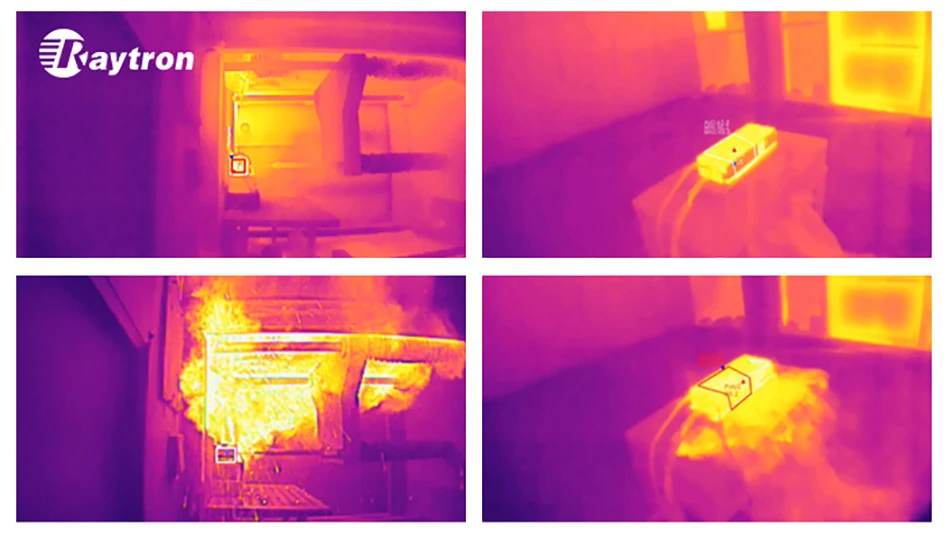

As the global electric vehicle (EV) sector accelerates, lithium-ion battery thermal runaway remains an urgent safety challenge for the automotive industry. Recent lithium fire incidents underscore the urgent need for non-intrusive, proactive and high-precision monitoring solutions. Raytron has unveiled its AI-driven thermal imaging technology for monitoring the entire lithium-ion battery lifecycle to prevent catastrophic failures.

What is thermal runaway and why is it so dangerous?

Thermal runaway is a dangerous, self-sustaining chain reaction within a battery. It typically starts with a sharp rise in internal temperature and pressure, often prompting an alert from the battery management system (BMS). As pressure builds, the battery casing may vent, releasing hot, flammable, and often toxic gases and smoke, such as hydrogen fluoride and carbon monoxide.

These hazardous gases are easily ignited by the battery’s intense internal heat, leading to fire or explosion. What makes lithium-ion battery fires particularly dangerous is that the cathode material breaks down at high temperatures, releasing oxygen that fuels the flames. This makes the fire extremely difficult to put out – as standard fire extinguishers may be ineffective – and allows it to spread rapidly from cell to cell in a devastating domino effect.

A preventable tragedy: A case study

In October 2025, an electric vehicle spontaneously caught fire while driving in Shanghai. The official investigation revealed that the incident was caused by coolant leakage. The leaking coolant corroded the battery's aluminum plate, seeped into the battery pack, and made direct contact with battery cells. This led to an internal short circuit, which triggered thermal runaway. Within seconds, the vehicle was engulfed in flames. Had the subtle temperature differences within the battery – an early indicator of coolant penetration – been detected, this accident could have been prevented.

Why thermal imaging is essential for early-stage prevention

Infrared thermal imaging is a powerful, non-contact, non-destructive testing (NTD) method, vital for preventing catastrophic failures such as battery thermal runaway. Based on a fundamental physical principle – that all objects with a temperature above absolute zero (-273℃) emit infrared energy – this technology works by detecting this emitted radiation and converting it into intuitive thermal maps. The hotter an object is, the more infrared energy it radiates.

At the early signal detection, the thermal imaging instantly identifies minute hotspots, which are early indicators of internal shorts, high resistance connections, or cooling failures, well before they trigger a full-blown lithium battery fire. Raytron’s infrared thermal camera is very sensitive, detecting subtle temperature differences as small as 30mk (0.3℃), which is crucial for finding minor, localized faults. By integrating AI with thermal camera data, Raytron’s solution moves beyond simple temperature thresholds, analyzing temperature rate-of-rise and patterns to provide predictive warnings, effectively boosting the performance of traditional BMS.

How thermal imaging prevents thermal runaway across all stages

- In R&D: Infrared thermography cameras validate battery thermal management system (BTMS) and structural safety by precisely capturing heat propagation during stress tests, allowing engineers to design effective containment against thermal runaway battery spread.

- During production: Raytron’s TN220 thermographic cube camera is used for critical quality control. It screens out high-risk cells with micro-shorts or welding defects by detecting abnormal heat during fast charge/discharge, thereby eliminating latent failure points.

- In logistics: 24/7 thermal imaging scanners monitor warehouses for spontaneous hot spots, ensuring early intervention to prevent a costly lithium fire.

- In after-sales service & maintenance: Handheld thermography cameras enable maintenance crews to quickly locate faulty cells or high-resistance connections, stopping minor heat anomalies from escalating into a full thermal runaway event.

Latest from EV Design & Manufacturing

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals

- EMCO presents Ecomill Plus HPC3 milling machine

- Discovery paves way for safer, higher-performance batteries