AdobeStock_258888395-JYPIX

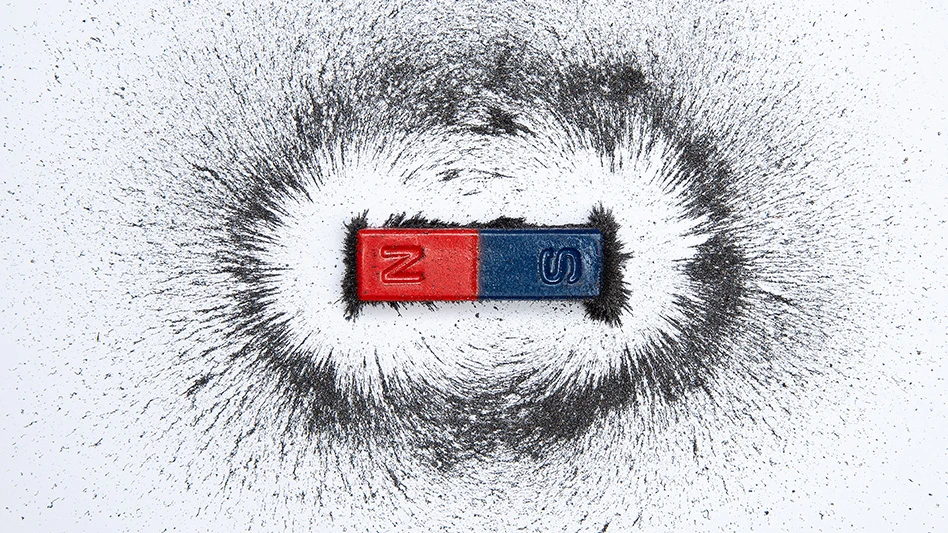

As the world races toward carbon neutrality, electric vehicles (EVs) are surging ahead. But the boom in lithium-ion batteries (LIBs), the high-energy hearts of EVs, smartphones, and more, brings a hidden danger: counterfeit or low-quality non-OEM batteries slipping into the mix. Reports highlight fires and explosions from these substitutes, especially in e-bikes and cameras, where overcharging or degradation turns them into ticking time bombs. Traditional safeguards like barcodes or IC chips? Easily faked or swapped. Researchers, however, are exploring the idea of harnessing the invisible magnetic fields generated by the batteries themselves during charge-discharge cycles. Building on prior nondestructive tech for spotting battery faults, this research pioneers magnetic analysis to authenticate LIBs right onboard vehicles, ensuring safety without invasive checks and paving the way for trustworthy EV adoption worldwide.

Results and benefits

The study, published in Green Energy and Intelligent Transportation, put prismatic LIBs – common in hybrid electric vehicles (HEVs) – under the magnetic microscope, measuring fields around cells with varying internal structures using sensitive sensors. Key findings? Distinct magnetic signatures emerged on the short sides of the cells, tied directly to differences in current collector shapes. For instance, simulations and real measurements showed clear variations in field distributions, reproducible even when scaling up to modules with two cells in series, where adjacent fields either amplified or canceled out predictably. Remarkably, identification boiled down to just two strategic sensor points per cell, with low variability and a linear relationship between current and magnetic field – meaning instant, proportional detection without complex setups.

Socially, these breakthroughs spell massive wins: fewer battery-related fires mean safer roads and homes, potentially saving lives and cutting insurance costs. For automakers and consumers, it guarantees genuine parts, boosting EV reliability and longevity – LIBs already outlast nickel-cadmium rivals with higher energy density. Environmentally, by curbing faulty battery waste, it supports sustainable tech cycles. Experimental data backs this: magnetic resonance imaging (MRI)-inspired methods detected defects noninvasively, while algorithms mapped 2D current distributions, proving the tech's precision for real-world applications like EVs and battery-powered gadgets.

Future application prospects

Imagine EVs that self-verify their batteries at startup, flashing a warning if a counterfeit sneaks in – stopping disasters before they start. This magnetic ID system could integrate into battery management systems (BMS), enhancing state-of-health (SOH) tracking alongside voltage and temperature monitoring. Scaling up, it applies to cylindrical cells in full EVs or even larger packs, with simulations adapting to varying cell distances or counts.

Further research might blend machine learning for predictive field mapping or gas emission cross-checks for hybrid diagnostics. Practically, it could standardize safety protocols for global fleets, enabling traceability from factory to road and fostering innovations such as vehicle-to-grid energy sharing, where authenticated batteries ensure grid stability. Ultimately, this refines EV ecosystems, making them smarter, safer, and more efficient for a greener future.

Latest from EV Design & Manufacturing

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals

- EMCO presents Ecomill Plus HPC3 milling machine

- Discovery paves way for safer, higher-performance batteries