Ceratizit

A recent Forbes article stated some European countries plan to eliminate sales of fossil fuel-powered cars by 2030, with most of the E.U. joining the battery-powered electric vehicle (BEV) club soon after. Here in the U.S., California, New Jersey, and several other states are taking similar measures, as is Canada, although the federal government remains more conservative. The New York Times recently reported six major automakers including Ford, General Motors, and Mercedes-Benz pledged to stop building gasoline and diesel-powered vehicles by 2040 at the latest.

Those are two examples of flotsam in EV news articles published each week, all of them discussing the impending demise of the internal combustion engine (ICE). And whether you agree on the timing, science, or policies surrounding this four-wheeled revolution, the writing is on the wall: battery-powered vehicles represent the future of road transportation.

Anatomy of an EV

There’s one thing pundits fail to mention, the tremendous upheaval coming to the factory floors of the companies producing the vehicles. Yes, a BEV has four wheels, various body panels, and a chassis, but the technology under all that sheet metal and plastic is far different than its predecessors. Manufacturing in an efficient, cost-effective manner requires retooling, redesign, and especially rethinking of existing processes.

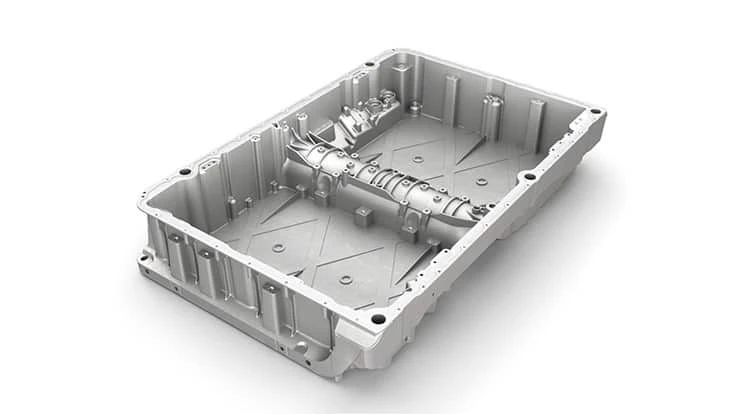

The most obvious change is the need for batteries, lots of batteries. Depending on the manufacturer, a typical BEV might contain thousands of Li-ion cells, about the size of the AA batteries in your TV’s remote control. Each is carefully packed into precision-machined battery trays made of high-silicon aluminum, then surrounded by sophisticated electronics, fireproofing material, and cooling systems. Producing these trays calls for high-performance milling cutters and indexable form tools, using polycrystalline diamond (PCD) to withstand the abrasiveness of the aluminum alloys while delivering smooth, flat sealing surfaces, and maximum productivity.

The motor is just as important. Unlike those relying on fossil fuels for power, electric motors are quite simple in concept, comprised of the stator housing and its spinning, copper-wound rotor within. Of course, there are also electronic controls, various hardware items, bearing packs to support the rotor, and a cooling system to dissipate the immense heat generated within, but in terms of reduced part count, electric motors easily win. Lightweight aluminum is the metal of choice for the housing, although a high-strength alloy steel is typically used for the rotor shaft, and rare earth metals like neodymium and yttrium for the magnets.

A gearbox is attached to the motor’s end, not the size and complexity of the six- and eight-speed transmissions which drivers have become accustomed over recent decades. Because electric motors can operate over a much wider speed range and produce torque even at zero RPM, a single-speed gear arrangement is often sufficient to drive the vehicle. Some manufacturers also use separate motors for each axle or even one for each wheel. EV drivetrains and their manufacturing are far simpler than their gas-driven counterparts.

Big changes afoot

Due to the simpler construction of EVs, manufacturing is easier than with conventional automobiles. Automakers are sorting out details as they work towards optimal designs. Machine shops face new component shapes and sizes, but production quantities that fall short of what automakers and their suppliers are used to processing. They need flexibility, advanced tooling, and machinery to remain competitive with constantly evolving demands.

https://cuttingtools.ceratizit.com

On the plus side, none of the materials involved are new, and EV component suppliers have machined the same aluminum and steel for decades. There's plenty of composites in use in the automotive industry but they represent a small percentage of a vehicle’s bill of materials.

Cutting tools need to efficiently cut conventional materials in novel shapes and relatively small quantities. Consider the EV motor housing. A typical bore size measures 200 mm or more, requiring a cutting tool whose weight if made conventionally would outstrip the spindle and tool changing capacities of all but the largest CNC machining centers.

The solution is lightweighting the tool using a combination of composite materials and to 3D print it. These specialized cutting tools are often constructed of modular components, allowing their users to meet changing customer demands without retooling. Similar examples exist elsewhere in an EV drivetrain. Multifunction, indexable drills produce complex holes, and counterbores in a single operation, while traditional threading methods like tapping and rolling are discarded in favor of far more flexible milling cutters able to drill, chamfer, and thread in one step.

Viva la revolución

There’s more to the EV story than advanced cutting tool technology. There’s also Industry 4.0 and the Industrial Internet of Things (IIoT). They're giving EV manufacturers new capabilities only dreamed of a decade or two ago. Many of the cutting tools discussed can be equipped with sensors that monitor machining forces and vibration, sending signals to an equally smart machine controller that alters feedrates or spindle speeds to optimize the machining process. Such process monitoring also gives factory floor management greater insight into the production processes, allowing them to take proactive steps to counter unfavorable trends, or find ways to further increase efficiency.

https://cuttingtools.ceratizit.com

This technology is also available to traditional automobile manufacturers, and many have already begun using it. But it’s BEV production with its relative youth, faster rate of change, and subsequent need for higher flexibility that stands to benefit the most, and have the greatest chance of rapid, successful implementation. Achieving this, will entail working with tooling suppliers that are knowledgeable and equally flexible, able to deliver cost-effective solutions on abbreviated timelines. It’s through strong partnerships such as these, with a corporate-wide embrace of modern manufacturing technology that BEV producers will speed their way through the coming EV revolution.

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals