Ford Motor Company

The launch of the all-new, electric F-150 Lightning pickup is a milestone moment in America’s shift to electric vehicles.

F-150 Lightning trucks are now being built for customers across America. F-150 Lightning is the fastest-accelerating F-150 yet and the only full-size electric pickup available now with a starting price less than $40,000.

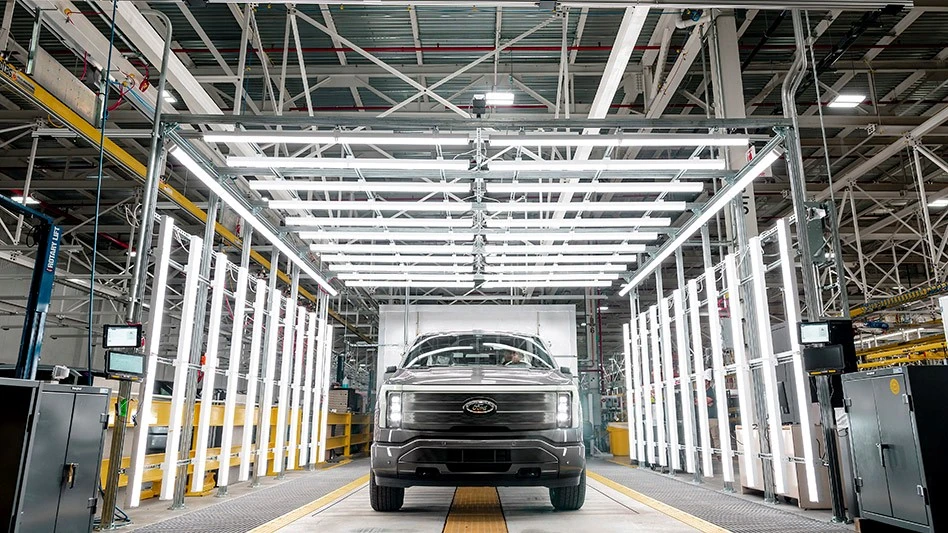

Built at the ultra-modern Rouge Electric Vehicle Center within Ford’s historic Rouge Complex, F-150 Lightning is the only electric vehicle that is Built Ford Tough. Ford F-Series has been America’s best-selling truck for 45 years in a row and is second only to the iPhone in revenue among all American consumer products, according to a 2020 study.

“We celebrate the Model T moment for the 21st Century at the Rouge Electric Vehicle Center,” said Ford Executive Chair Bill Ford. “The Rouge is where Ford perfected the moving assembly line, making it a fitting backdrop as we make history again. The stunning anticipation for F-150 Lightning is a credit to the work of our Ford engineers and designers, and the UAW team members who are building these trucks with pride.”

Ford has unprecedented demand for F-150 Lightning with 200,000 reservations and is expanding the Rouge Electric Vehicle Center to ramp up production to a planned annual run rate of 150,000 in 2023. The company has invested a total of $950 million and created 750 jobs at the Rouge Electric Vehicle Center. Ford’s investment in Michigan for F-150 Lightning alone now totals more than $1 billion, with 1,700 recently created jobs spread among five Ford plants in the state, including Van Dyke Electric Powertrain Center, where Lightning electric motors and electric transaxles are assembled, and Rawsonville Components Plant, where Lightning batteries are assembled.

“America’s real transition to electric vehicles starts now,” said Ford President and CEO Jim Farley. “F-150 Lightning is just the beginning of our ambitions for growth and leadership in digital, electric vehicles. We continue to expand our EV manufacturing footprint across the U.S., including the start of site preparation at BlueOval City, which will enable us to meet the ever-increasing customer demand for our exciting EV line-up.”

Ford is on track to deliver more than 2 million electric vehicles annually by 2026, equal to about one-third of the company’s global volume, on the way to 50% by 2030.

With acceleration from zero to 60 mph in the mid-4 second range with the extended-range battery, the freedom of a 10-kilowatt smart power plant on wheels, a starting price less than $40,000 before available tax credits and software updates that will make it even better over time, F-150 Lightning is attracting new customers to Ford. A full three-quarters of reservation holders do not currently own or lease a Ford vehicle. F-150 Lightning is also converting many of them to first-time truck or electric vehicle buyers.

Ford announced its intention to build the Rouge Electric Vehicle Center at its historic Rouge complex 19 months ago, in September 2020, and has since created an ultra-modern site leveraging more than 118 years of expertise in manufacturing at scale.

Ford remains the top automaker in America in terms of U.S. production, sales of U.S.-made vehicles and employment of hourly autoworkers.

“For UAW Ford members, the launch of the Lightning F-150 is an example that when electric vehicle expansion is done right, it can create good paying union jobs and opportunities,” said UAW President Ray Curry. “Today’s launch demonstrates that we can create a win-win for UAW families and communities as we build EV products for decades to come."

The manufacturing technology in the Rouge Electric Vehicle Center is just as innovative as the F-150 Lightning. It is the first Ford plant without traditional in-floor conveyor lines and instead uses robotic Autonomous Guided Vehicles to move F-150 Lightning trucks from workstation to station in the plant.

These Autonomous Guided Vehicles create more flexibility in the plant for additional production output, quality checks and product customizations, among other benefits. And changes can be made quickly without the constraints of a typical line that requires the installation of floor chains, moving mats, conveyors, and overhead cranes. The plant also uses cobots, or collaborative robots, that work side-by-side with people without any safety cages needed. These cobots help with tasks that would be ergonomically challenging for employees, while also keeping employees safe.

“Today UAW members begin a new generation of building the iconic F-150, crafting a game-changing electric vehicle backed by our UAW craftsmanship and quality assembly,” said Chuck Browning, UAW vice president, director, Ford Department. “Our members are proud of building Ford Tough and are excited to build this new Lightning EV with the same UAW care and legendary performance Ford customers have grown to expect.”

The Rouge Electric Vehicle Center is a zero-waste-to-landfill site, meaning none of the material generated as a by-product of the manufacturing process will go to landfills. The plant was built on the former Dearborn Assembly Plant site, using materials from the prior plant in the foundation.

Ford is committed to achieving carbon neutrality by 2050, and to using 100% local, renewable electricity in its manufacturing operations by 2035.

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals