AdobeStock | 222981054-sittinan

The global electric vehicle (EV) battery market has undergone significant shifts in recent years, making the future difficult to predict. Some reports from earlier this year estimate global demand for EV batteries could more than triple by 2030, growing from about 1 terawatt-hour (TWh) in 2024 to more than 3TWh. We’ve also seen investments in U.S.-based EV battery manufacturing plants, creating thousands of new jobs and strengthening the domestic supply chain.

Despite these signs of optimism and growth, the industry is also dealing with reports of overcapacity and softening demand in the near term. A recent report from S&P Global found that 60% of consumers believe battery-electric vehicles (BEVs) are too expensive and that demand for these vehicles in the U.S. has stalled – or moved towards hybrid options.

This begs the question: how can battery manufacturers thrive amid so much uncertainty?

Staying agile with smart manufacturing technologies

With an uncertain future for EV batteries, it’s important for manufacturers to stay agile. Halting production entirely only to restart months later (or land on a new production direction) can be costly and disruptive, causing talent to look for new roles and manufacturers to lose productivity.

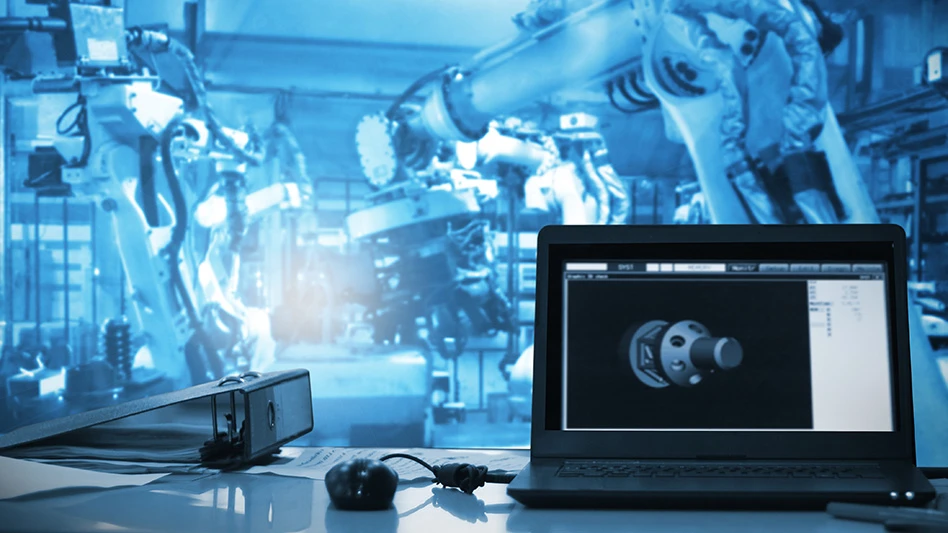

By leveraging advanced technologies such as artificial intelligence (AI), high-performance robotics, and advanced data analytics, manufacturers can adapt their production lines more efficiently, improve overall operations, and reduce waste.

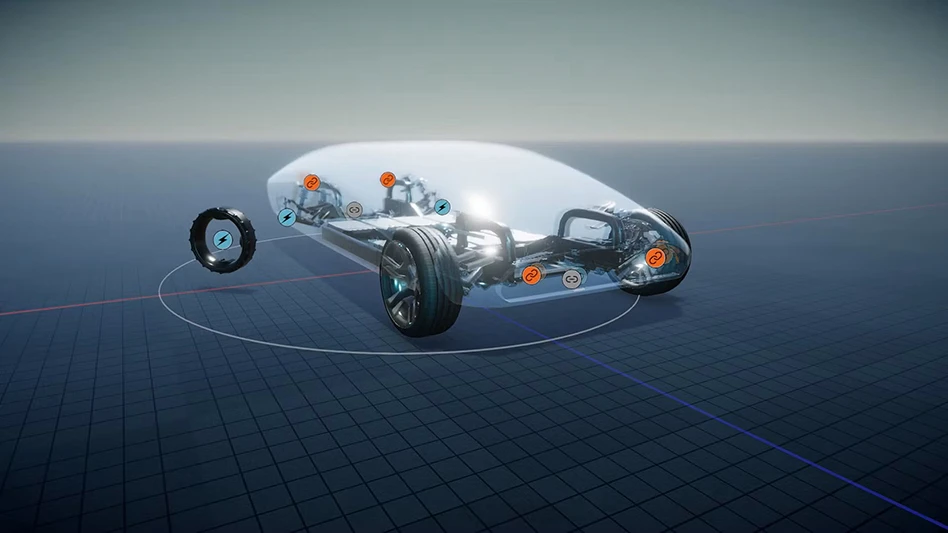

However, as these technologies are increasingly integrated across production lines, managing the growing network of machines, data, and processes becomes complex quickly. That’s where smart manufacturing solutions such as manufacturing execution systems (MES) and digital manufacturing platforms (DMP) come into play.

MES and DMP are software solutions that connect every part of the production process, giving manufacturers a comprehensive view of everything happening on the factory floor. By connecting production lines, capturing real-time data, and streamlining workflows, these systems act as a single source of truth for all operations. The result is improved decision making, greater efficiency, more consistent quality, and the ability to respond quickly to supply chain shifts or design changes – all critical advantages in today’s everchanging market.

Reducing costs and increasing efficiencies to stay ahead

One way for EV battery manufacturers to stay competitive in today’s environment is to reduce costs and increase efficiencies, ensuring they remain profitable even as demand fluctuates. This is easier said than done.

MES and DMP solutions play an important role in achieving these goals. With real-time visibility into every step of production, manufacturers can identify inefficiencies, reduce downtime, and minimize material waste. They also help streamline workflows through automation and data integration, ensuring every machine, process, and operator is working in sync. This prevents data silos and results in a smarter, leaner factory that can maintain profitability and agility even when market conditions change.

Imagine a coating machine that begins to struggle with scraping excess slurry off the electrode sheet. With MES software, manufacturers can quickly pinpoint where the issue originates and perform maintenance. With this information in hand, operators are able to address any potential failures before they turn into a bigger issue that stops production entirely. Access to real-time information prevents slowdowns and saves wasted labor, materials, and time, enabling manufacturers to keep efficiency high and costs low.

Maintaining high quality with increased traceability

Another way for EV battery manufacturers to stay competitive is by maintaining high quality through increased traceability. The National Highway Traffic Safety Administration shared that in 2024, there were 74 electric vehicle recalls, impacting more than 2.9M vehicles, demonstrating the importance of being able to track and trace all vehicle components to the originating source. With the ability to view and control end-to-end production through MES and DMP systems, manufacturers can ensure materials are used correctly, waste is minimized, and product quality standards are consistently met. These solutions also help prevent recalls that cost manufacturers time and money and put their reputations at risk.

Quality and traceability are extremely important in EV battery production. Even the slightest discrepancy in chemical mixing or assembly can lead to battery malfunctions, costly recalls, and safety concerns for end users. With the ability to track production from raw materials – at the individual cell level – to the final product, manufacturers can be confident their products meet regulatory requirements and help increase customer trust.

Supporting the next generation of batteries

Lithium-ion batteries are currently powering the majority of the world’s EVs and consumer electronics. These batteries are made up of a mix of raw materials including lithium, cobalt, nickel, manganese, graphite, and aluminum. The raw materials needed for the production of these batteries are expensive and involve a complex supply chain, driving up prices of EVs.

To help combat this issue, next generation battery technologies, such as flow batteries and solid-state batteries, are increasing in popularity. These new battery technologies may bring improved performance, increased safety, and potential cost savings. As battery technologies evolve, manufacturing processes must evolve as well.

With production lines already set up, EV battery manufacturers can readily transition their lines to support new battery technologies. Having MES and DMP systems ingrained in operations makes this process simpler for operators. DMP systems enable manufacturers to model a mix of multiple manufacturing types in a single factory.

Additionally, with new battery technologies comes the need to train and upskill workers on the nuances involved in manufacturing next-gen batteries. MES and DMP solutions help manufacturers codify processes and workflows directly in the system, providing a solid foundation for all workers to reference and learn from. This streamlines onboarding and equips workers with the information they need, ensuring everyone on the factory floor is aligned and up to date.

EV battery manufacturing in 2026 and beyond

The future for EVs remains uncertain, and the industry is balancing the needs of a skilled workforce, raw materials, intelligent machines, and fluctuating demand. The only way to make informed decisions on how to proceed is through a view into all aspects of the factory floor.

MES and DMP solutions provide manufacturers with the big picture, giving them freedom to evaluate their options and determine the best path forward – whether it be sticking to the course, diversifying their products, or entering new markets.

About the author: Eric Symon is head of Smart Manufacturing at Panasonic Connect North America. Eric has held executive positions at market-leading software and professional services companies delivering value through digital transformation to customers in manufacturing, aerospace and defense, and retail industries. Eric holds a B.S. from the Pennsylvania State University.

Latest from EV Design & Manufacturing

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals

- EMCO presents Ecomill Plus HPC3 milling machine

- Discovery paves way for safer, higher-performance batteries

- #77 Manufacturing Matters - Supply Chain - Smoothing Out or Something Else? with Lisa Anderson

- Take a seat at the table for the latest in manufacturing automation