Mercedes-Benz

Mercedes-Benz will build ultra-high-performance axial-flux electric motors at its Berlin site, as the luxury car brand prepares to go all electric by 2030. With the transformation of the Berlin site, Mercedes-Benz will reach new digitalization and electrification milestones on the way towards a sustainable and emissions-free future.

Mercedes-Benz announced the acquisition of YASA, UK-based manufacturer of ultra-high-performance electric motors in the summer of this year, securing access to unique axial-flux technology, increasing its vertical integration and value creation in development and production. The portfolio of the Berlin plant already includes assembly volumes of electric drive units and the so-called EE Compartment.

The Mercedes-Benz Digital Factory Campus for the development, testing and implementation of pioneering MO360 software applications has reached an advanced stage. A series of pilot lines will go into operation next year. Berlin will become the competence center for digitalization in the global Mercedes-Benz production network and support the worldwide rollout for new releases and apps in the MO360 ecosystem. The campus will become a MO360 training and qualification center with innovative approaches in digital implementation. Mercedes-Benz is investing a low triple-digit million euros amount in the transformation of its Berlin plant within the next six years.

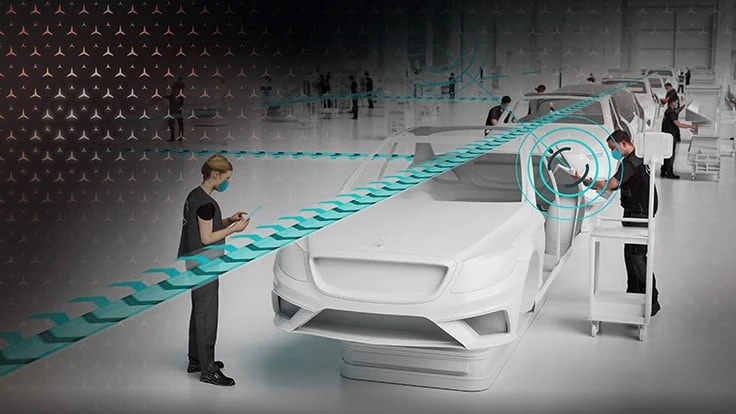

MO360 - The digital ecosystem

The digitalization of production is an important success factor for Mercedes-Benz. The digital MO360 ecosystem was launched last year. Large parts of the modular and expandable system are already in use at around 30 Mercedes-Benz plants worldwide. As a competence center for digitalization, the Mercedes-Benz Digital Factory Campus will drive the development, testing, and validation of future software applications and concepts for MO360 from next year onwards in a real production environment. The aim is taking the new developments tested in Berlin and to roll them out worldwide and to qualify the users in the plants.

The highlights of MO360 include:

- Increase in production efficiency using MO360

- Different tools combined into one tool family with a unified user interface

- Digital Shopfloor Management to help organize production

- Digital Worker Assistance to support assembly activities

- Quality Live is all about product quality

- The MO360 Data Platform provides the fundamental basis for workers to access and analyze all data in their field of responsibility, regardless of their IT skills. The MO360 Data Platform is the "digital twin of production". It makes a decisive contribution to the democratization of data and, with the help of artificial intelligence and predictive tools, supports the qualification of employees in the context of the transformation.

Cooperation with science and industry

With its broad spectrum of MO360 software applications, the Mercedes-Benz Digital Factory Campus also aims to collaborate with partners from business and science, universities, research institutions, and innovative industrial companies. Mercedes-Benz and Siemens announced in March they would work together on the sustainable digitalization and automation of the automotive industry with the support of the state of Berlin. As a provider of automation, industrial software, and intelligent infrastructure, Siemens is contributing its technologies to develop highly flexible, efficient, and sustainable automotive production with Mercedes-Benz.

"We have further expanded our successful cooperation with Mercedes-Benz in Berlin in recent months,” says Cedrik Neike, Siemens AG and CEO Digital Industries Together, we are proving that state-of-the-art technologies can also make existing production facilities fit for the future. We are thus taking a major step towards sustainable and even more competitive automotive production. The future of mobility begins in the production hall. And technology from Siemens enables this transformation towards electromobility. This makes us proud."

Business and politics support transformation in solidarity

The state of Berlin supports the transformation of the Mercedes-Benz site in Berlin as well as the partnerships with Siemens and other companies and institutions that are part of the excellent science and start-up landscape in Berlin.

“For the production an innovation location Berlin the ongoing transformation of Mercedes-Benz in Marienfelde is good news,” says Berlin Mayor Michael Müller. “The development of the Berlin plant into a center of competence and as a driver of digitalization and production of e-mobility strengthens the role of Berlin within the company and advances Berlin as a location for science and innovation. Beyond this I welcome the education and qualification activities since this is an important step towards creating future-proof industrial jobs in Berlin. I wish the Berlin plant and its employees lots of success in this ambitious endeavor!”

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals