CREDIT: FEV

FEV has partnered with the Teaching and Research Area Mechatronics in Mobile Propulsion (MMP) at RWTH Aachen University to develop a modular concept for electric drive units. The approach significantly reduces dependence on critical raw materials such as rare-earth magnets in electric machines. The objective is to completely eliminate the use of rare-earth elements, which are costly and available only in limited supply. Their mining also presents significant environmental and geopolitical challenges.

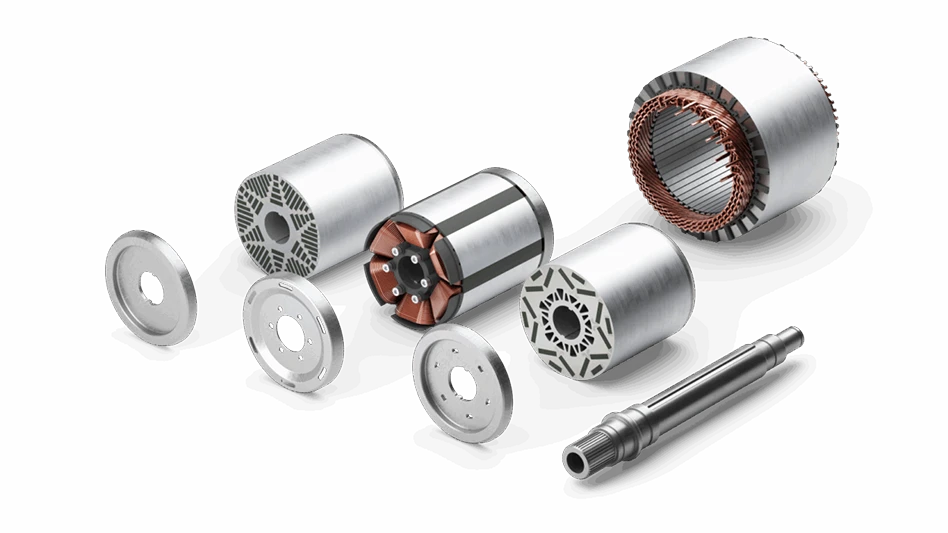

The developed concept uses a design with a common stator, housing, cooling system, and converter, while the rotors are interchangeable. Studies have shown that the rare-earth-free alternatives can achieve overall efficiencies of up to 94% while offering lower cost volatility and reduced CO₂ equivalents over the entire life cycle.

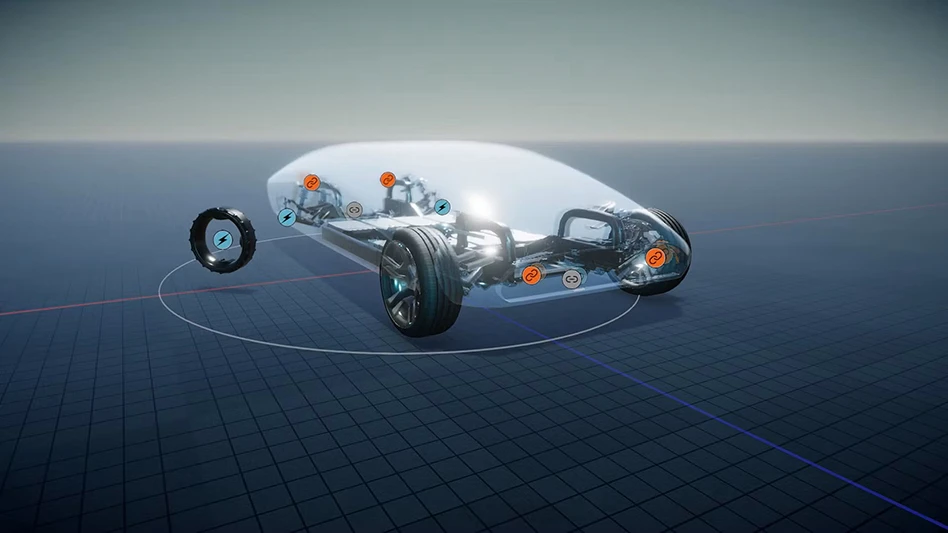

Permanently excited synchronous machines with rare-earth magnets are the most common type of drive found in today’s electric vehicles (EVs). The high magnetic flux density of the permanent magnets enables optimum efficiency and excellent performance in a compact design. However, for the reasons mentioned above, this technology is associated with growing risks. For their study, experts from FEV and RWTH Aachen University developed solutions using electrically excited synchronous machines and ferrite-based electric machines, as well as asynchronous machines, and examined them in terms of performance, cost, and environmental compatibility. The platform concept is engineered to meet varying power demands in the mid-range (C segment) and luxury (D segment) vehicle classes, delivering peak outputs of 160kW and 250kW respectively. It also supports scalable adaptation for lower vehicle segments through modular design.

A central element of the concept is an innovative oil cooling system with direct stator and rotor cooling, which enables a significant increase in continuous power. The resulting ratios of continuous to maximum power significantly exceed those of conventional systems by up to 75%.

Future-proof prospectives for OEMs

“Our platform approach allows vehicle manufacturers to react faster and more flexibly to market shifts, raw material shortages, and cost fluctuations. This is achieved without compromising efficiency or performance,” says Patrick Hupperich, president and CEO of FEV Group.

The modular unit enables different drive concepts to be realized using the same stator and converter by simply changing the rotor. This flexibility allows OEMs to diversify their supply chains and reduces development costs. Additionally, it lowers overall costs through economies of scale. In addition, the rare-earth-free alternatives offer the opportunity to combine technological diversification with sustainability goals.

Latest from EV Design & Manufacturing

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Machine tool geared toward automotive structural components

- Discovery paves way for safer, higher-performance batteries

- #77 Manufacturing Matters - Supply Chain - Smoothing Out or Something Else? with Lisa Anderson

- Take a seat at the table for the latest in manufacturing automation

- A strategic deep dive into resilient manufacturing platforms

- Murata honored for automotive camera, sensor augmentation technology