Nuvola

Nuvola Technology (formerly Millibatt), a venture-funded battery materials start-up, announces its patented SafeCoat Direct Deposition Separator (DDS) material that eliminates the primary cause of lithium-ion battery fires. SafeCoat replaces the troublesome plastic sheet separator material used in today's battery manufacturing process. Its ingenious spray-on coating fully encapsulates and protects the battery's electrodes from a thermal runaway and a potential fire. Nuvola was selected as one of ten winners in LG Energy Solution's annual 2022 Battery Challenge, competing with over 100 companies. The LG Battery Challenge competition is designed to accelerate the adoption of new battery technologies and business models.

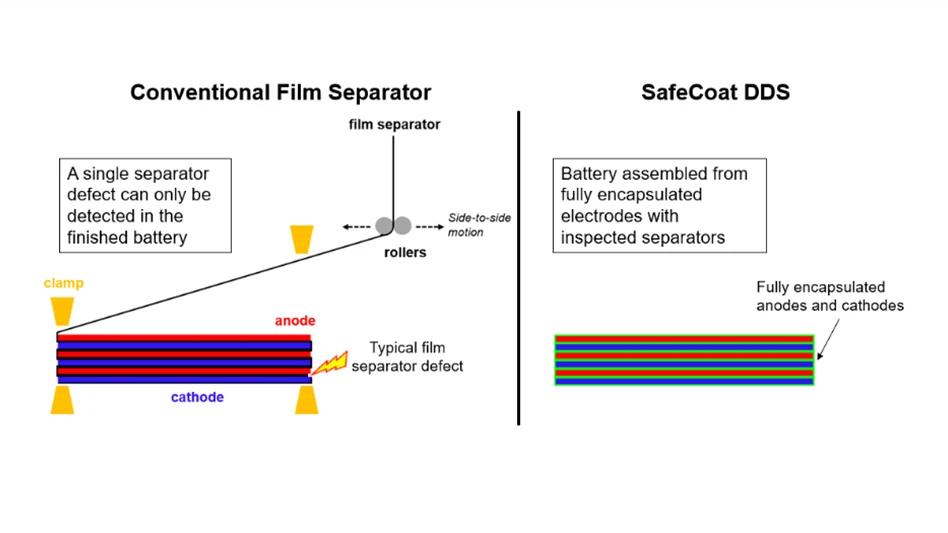

The primary cause of battery fires is a manufacturing error internal to the battery cells of today's electric vehicles (EVs), e-scooters, e-bikes, and cell phones. These batteries can contain thousands of tissue-paper thin folded sheets of a porous plastic membrane that keeps the internal battery electrodes from coming in contact. This 50-year-old sheet separator technology is prone to manufacturing assembly errors and failure. During the battery assembly process, a single sheet separator can become damaged, creating an undetectable wrinkle, misalignment, misfolding, or even a tiny tear allowing the electrodes to come in contact. This may cause a fire -- days, months, or years later. SafeCoat solves this safety issue by replacing the sheet separator with a sprayed polymer electrode coating that ensures the electrodes never come into contact.

"Improving battery safety is one of the highest priorities for the EV market, with large, energy dense batteries representing a significant threat to public safety in the event of a fire," says James Hodgson, Research Director, Automotive at ABI Research. "Nuvola Technology’s approach of separator coating offers the opportunity to improve both safety and production yield by modifying one step of the manufacturing process.”

The recent EV and e-bike fires are examples of this insidious and tragic battery failure that SafeCoat can eliminate. The Nuvola SafeCoat product is now under evaluation by several major battery and car manufacturers, with products utilizing the technology expected in the market in 2025.

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals