Ultraseal International

The shift away from the internal combustion engine

The shift away from the traditional internal combustion engine is gaining momentum and with an estimated one billion vehicles across the planet there is a conscious effort to reduce harmful emissions, backed by greener government initiatives. The initiatives do their part when it comes to sustainability but it’s down to the manufacturers to develop new automotive designs, using environmentally friendly powertrains, lighter weight materials, thinner walled castings, and production processes such as die casting to reduce weight.

With an increasing focus on creating greener methods of transport and meeting zero emissions targets, automotive manufacturers are focused on lightweight vehicle parts and structures. This importance is paramount in EV compared to traditional (internal combustion engine) automotive production.

A significant challenge facing the EV market is range, positioning EV’s behind the internal combustion engine. Battery technology will have to improve, and electric vehicles will have to become lighter, and weight significantly reduced to overcome this challenge. An average battery pack weighs around 200 kg – 300 kg. Automotive manufacturers continue to embrace thinner-walled castings, lighter materials, and new technologies in a bid to reduce vehicle weight.

The demand for better efficiency

While the die casting process is an essential manufacturing method for automotive production, it’s not without challenges including porosity. As vehicle manufacturers pursue lighter cars, the problem of porosity increases.

To reduce vehicle weight, die casters cast thinner wall components, bringing an increased risk of porosity creating a leak path. There is a greater risk of the microscopic holes forming in a part during the casting process interconnecting, and creating a continual leak through the component, the part may not be functionally sound because pathways allow gases, fluids, or oils to escape rendering the part unusable.

The solution to this problem is vacuum impregnation, sealing leak paths and porosity in metal castings. Specialist impregnation equipment is used to fill microscopic holes and leak paths with liquid sealant under vacuum, transformed into a chemically and thermally resistant polymer by heating.

Using this process allows die casters to produce thinner walled castings without the risk of leak paths where liquids and gases can escape under pressure. Impregnation offers huge cost and efficiency savings as defective parts could be scrapped.

Vacuum impregnation gained traction the last few years and will continue to as the EV market goes from strength to strength. Vacuum impregnation gives manufacturers more confidence discarding parts affected by porosity will be a thing of the past.

Why work with Ultraseal?

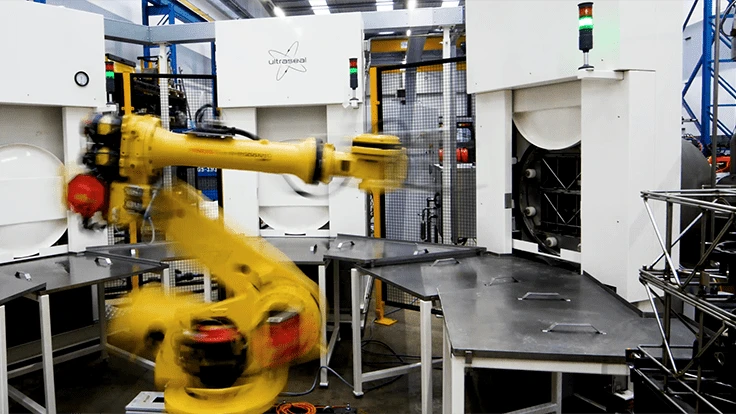

Ultraseal is leading the way in sustainability with vacuum impregnation and porosity sealing. With solutions to help manufacturers seal porosity in their die casting operations, Ultraseal has a closed-loop vacuum impregnation system, capable of recycling 95% of chemicals.

This provides commercial and environmental benefits since these chemicals are flushed with wastewater. Another plus of using the technology is the closed-loop system, a leaner alternative to other methods, offering less equipment downtime emptying, cleaning, and refilling tanks.

As the automotive sector and the manufacturing of EVs grows, companies will continue to invest heavily in the electrification of their product ranges to future-proof their business and stay relevant in the marketplace.

Incorporating vacuum impregnation into manufacturing will help the automotive industry reduce scrap and material waste, improve component life cycles, and improve environmental performance.

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals