CREDIT: SAKUU

Sakuu, a provider of commercial-scale equipment to the battery and supercapacitor manufacturing industries, has released performance data on the breakthrough cycle life longevity of battery electrodes produced by the Sakuu Kavian Manufacturing Platform with a fully dry processed cathode. Kavian enables high quality, customizable, mass-scale, and cost-effective dry electrode printing – supplying benefits that solve foundational challenges confronting mainstream battery manufacturers today.

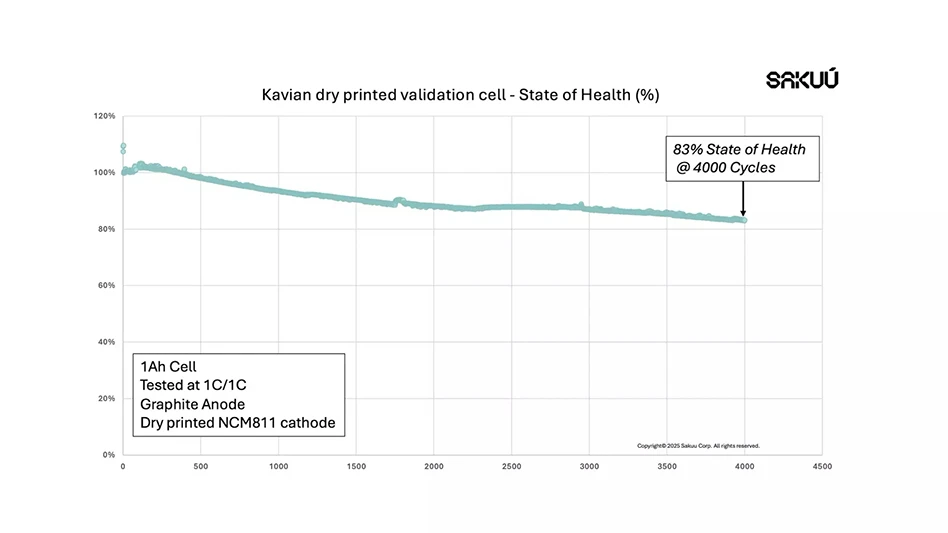

Test data confirms that a nickel cobalt manganese (NCM) battery cell manufactured on the Sakuu Kavian platform retains 83% charge after 4,000 cycles, a milestone in battery viability when using a fully dry process to print the cathode, putting it at the forefront of commercially available lithium-ion batteries found in electric vehicles (EVs) and other mass energy storage applications. (For comparison, a typical NCM battery cell should cycle more than 2,000 times while retaining at least 80% state of health for minimum EV viability.)

“We’re so proud of the performance of Kavian-manufactured battery electrodes,” says Robert Bagheri, Sakuu founder, CEO, and executive chairman. “Our extensive testing confirms that Kavian’s dry manufacturing process can be reliably trusted to deliver a product that will meet or exceed the capabilities of current wet processes. This again dispels any doubts as to the suitability of using a dry process for printing lithium-ion (Li-ion) battery electrodes. This myth-busting achievement is a testament to our materials engineering expertise, as customers tell us other additive manufacturers experimenting with dry processes struggle to achieve satisfactory results across the entire printed electrode – particularly the cathode.”

The Li-ion battery validation cell is manufactured on Sakuu Kavian without any new materials or optimization:

- 1Ah cell

- Cycled at 1C/1C

- Graphite anode

- Fully dry printed NCM811 cathode

A battery manufacturing milestone

The dry process enabled by Kavian is an innovation that addresses key challenges in scalability, sustainability, safety, and performance, while still reducing cost and enabling manufacturers to regionalize production. Compared to traditional wet-coated electrode manufacturing, Kavian’s dry-process production meets or exceeds standard performance and quality requirements.

The Sakuu Kavian Platform currently dry prints both cathodes and anodes in NCA, NCM, LFP, LTO, graphite, and silicon-graphite chemistries; its flexibility also enables new chemistries, such as aluminum-ion or sodium-ion, and solid-state formulations.

Kavian also dry prints supercapacitor electrodes to meet the unique power needs of AI data centers where demand is surging. Moreover, the battery manufacturing benefits of Kavian in terms of sustainability, cost-savings, and efficiency also apply to supercapacitor manufacturing:

- 100% elimination of toxic solvents and water

- 60% smaller footprint of manufacturing floor space

- 30% savings in utility operating costs

- 55% reduction of CO2 emissions

- 20% reduction in capital equipment costs

The Sakuu team is working on fulfilling the first orders for Kavian and has already delivered hundreds of meters of high-quality dry electrode to customers.

Latest from EV Design & Manufacturing

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals

- EMCO presents Ecomill Plus HPC3 milling machine