Cleveland, Ohio – Tesla Inc. lost $330 million in the first quarter, or $1.33 per share after adjustments, significantly higher than the $0.82-per-share loss predicted by analysts. However, company officials said plans are on track to get to a 250,000-vehicle-per-year build rate on the Model 3 electric car by year’s end and reach a 500,000-vehicle-per-year rate by the end of 2018.

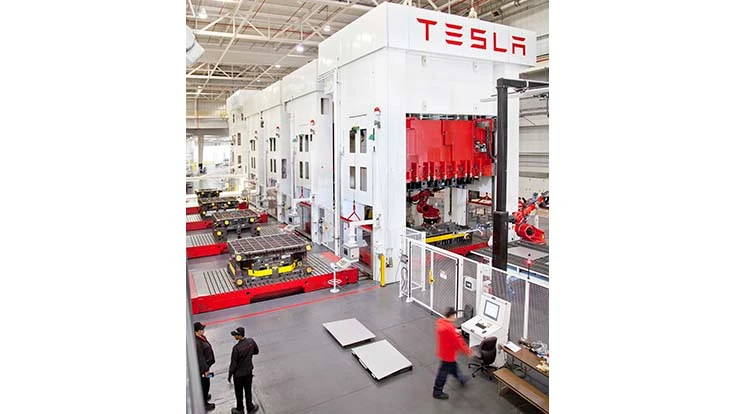

”We recently powered on our newest Schuler press line, and have started the commissioning process,” Tesla officials said. “This will allow sufficient time to install and tune die sets ahead of volume production. Paint shop preparation has been completed and installations of our dedicated Model 3 body welding and general assembly lines are progressing well. Equipment installation is also underway for volume manufacturing of cells, modules, battery packs and drive units at Gigafactory.”

Pre-production models using tooling similar to what Telsa hopes to use on the finished vehicle are on the road for testing.

During the first quarter, Tesla was on pace to produce about 100,000 vehicles this year, so getting the factory setup right would prepare the company for a 5x increase in capacity in less than two years.

Given that Tesla expects to end the year as a company with completely different manufacturing capabilities than the one that entered 2017, analysts have warned that the company’s current earnings and sales aren’t nearly as important as its preparedness to go into high-volume production of the Model 3. If the company can hit the targets it says it’s hitting, vehicle sales should rise dramatically, costs should fall, and Tesla could produce a profit.

During the quarter, increased sales led to increased costs, especially in research and development and selling/general administration. Tesla burned through $926 million of cash in the quarter ($553 million in capital expenses as it outfits its factory), but it raised nearly $1.6 billion in stock sales and debt, so it ended the quarter with more cash on hand then when it started, despite losing money on each vehicle sale.

About the author: Robert Schoenberger is the editor of Today's Motor Vehicles and a contributor to Today's Medical Developments and Aerospace Manufacturing and Design. He has written about the automotive industry for more than 17 years at The Plain Dealer in Cleveland, Ohio; The Courier-Journal in Louisville, Kentucky; and The Clarion-Ledger in Jackson, Mississippi.

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals