Volkswagen Group of America, Inc.

Volkswagen Group of America, Inc. and Redwood Materials, Inc. are creating a supply chain to recycle Volkswagen and Audi electric vehicle batteries in the United States, to provide accessible and more sustainable electric mobility for drivers. By advancing Volkswagen Group of America’s strategy to localize all major competencies for its electric transformation, and Redwood’s goal of creating the nation’s only closed-loop supply chain for lithium-ion batteries, the collaboration represents a crucial step in growing North America’s domestic EV industry.

“For Volkswagen, going all-in on electrification means driving sustainable solutions at every turn,” said Scott Keogh, President and CEO, Volkswagen Group of America, Inc. “Redwood Materials is a great partner to help us accelerate EV adoption in America. This collaboration allows us to move closer toward our goal of closing the loop for a circular EV economy, giving American consumers yet another reason to go electric.”

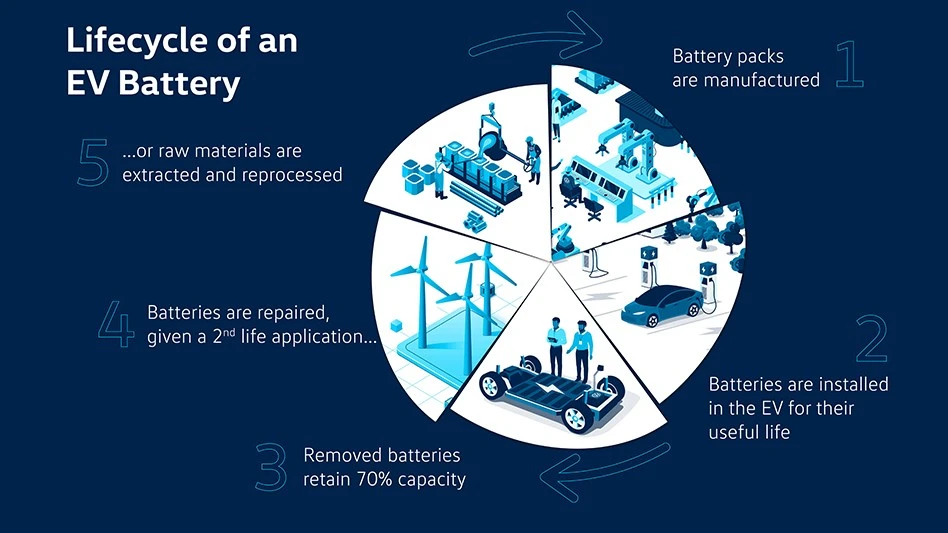

The new EV battery recycling collaboration will be facilitated by Volkswagen’s nationwide network of approximately 1000 dealers, starting with the Volkswagen and Audi brands. A holistic approach to the battery lifecycle is the key to the collaboration. The collaboration can support local battery capacity and expertise as Volkswagen continues its transition to an electrified portfolio by allowing for more sustainable utilization of battery components from the moment vehicles leave the assembly line through the end of their lifecycle.

As Volkswagen brands plan to introduce more than 25 new battery electric vehicles to American consumers through 2030, Volkswagen wants to establish battery recycling capabilities for current and future vehicles in North America now. The new EV battery recycling collaboration will integrate prototype batteries from Volkswagen’s research facilities such as the Battery Engineering Lab (BEL) in Chattanooga. Redwood Materials will work directly with dealers and Volkswagen facilities to identify end-of-life batteries and materials, safely package, and transport them to their Nevada facilities.

Redwood recycles more than 6GWh of lithium-ion batteries yearly, the equivalent of 60000 EV batteries. The batteries coming to Redwood are composed of end-of-life consumer devices, battery production scrap, and electric vehicle batteries, and represent most lithium-ion batteries recycled in North America. Redwood extracts raw materials such as cobalt, copper, nickel, and lithium, refines, and remanufactures them into critical battery components, anode copper foil, and cathode, before delivering the products back to domestic battery cell manufacturers.

“The transition to electric transportation and clean energy is coming and the batteries powering these technologies present an incredible opportunity. As more and more batteries reach end-of-life each year, an increasing and infinitely recyclable resource becomes available”, said JB Straubel, Redwood Materials Founder and CEO. “Redwood and Volkswagen Group of America share a vision to create a domestic, circular supply chain for batteries that will help improve the environmental footprint of lithium-ion batteries, decrease cost and, in turn, increase access and adoption of electric vehicles.”

The collaboration of Volkswagen Group of America and Redwood Materials reflects a shared vision for a circular EV economy that, if adopted across the industry, could help reduce battery costs and the need to mine and ship raw materials.

Volkswagen Group of America is aiming for 55% of its U.S. sales to be fully electric by 2030. To achieve this goal the company is transforming the North American region into an industrial EV powerhouse, featuring localized EV engineering and R&D capabilities, EV assembly and component production for its brands, and plans for a dedicated battery cell production.

Latest from EV Design & Manufacturing

- Festo Didactic to highlight advanced manufacturing training solutions at ACTE CareerTech VISION 2025

- Multilayer ceramic capacitor enters mass production

- How US electric vehicle battery manufacturers can stay nimble amid uncertainty

- Threading tools line expanded for safety critical applications

- #55 Lunch + Learn Podcast with KINEXON

- Coperion, HPB eye industrial-scale production of solid-state batteries

- Machine tool geared toward automotive structural components

- Modular electric drive concept reduces dependence on critical minerals